Inquiry / Contact

igus® inc.

Benefits:

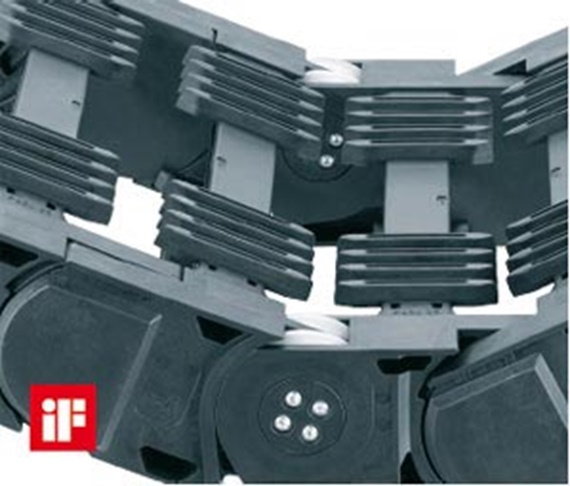

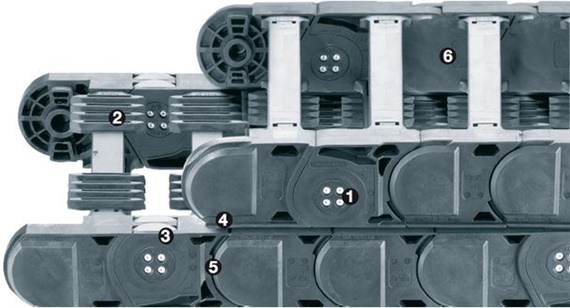

Low maintenance roller e-chain system® with tribo-optimized plastic rollers

2Comb-like AUTO-GLIDE crossbars

3Special design of the rollers and chain links therefore particularly quiet

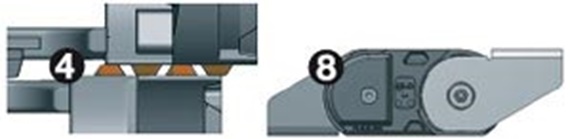

4Top and bottom run roll offset on top of each other

5Same pitch on roller/chain links

64 Inner height: 32 mm, 42 mm, 56 mm and 80 mm available

7Extension link solution available for even higher fill weights with 56 and 80 mm inner height

8Robust steel connection elements available

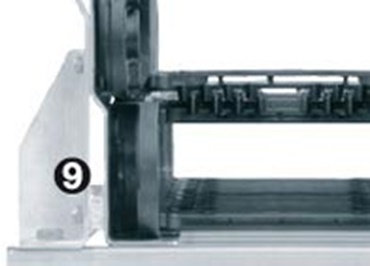

9Special P4 trough system available

Crane technology (in/outdoor)

Automated storage and retrieval system

Plant construction

Portal robot

Materials-Handling Technology

Mining

Steel works