Inquiry / Contact

igus® inc.

| Order no. | Bi [mm] |

Ba [mm] |

hi [mm] |

ha [mm] |

R [mm] |

||

|---|---|---|---|---|---|---|---|

| MF-06-10-018 | 0.39 | 0.75 | 0.43 | 0.67 | Upon request |

| further dimensions | |

|---|---|

| Installation height for the complete system: | 108,48 mm |

| Installation width of the complete system: | 29,5 mm |

| Recommended length of the trough sections: | 2.0 m, 3.0 m and 6.0 m - Material: Aluminum die-casting |

| Maximum cable/hose outer diameter: | Ø 8 mm |

| Order no. | Bi [mm] |

Ba [mm] |

hi [mm] |

ha [mm] |

R [mm] |

||

|---|---|---|---|---|---|---|---|

| MF-08-18-035 | 0.71 | 1.14 | 0.51 | 0.83 | Upon request |

| further dimensions | |

|---|---|

| Installation height for the complete system: | 161 mm |

| Installation width of the complete system: | 40,5 mm |

| Recommended length of the trough sections: | 2,0 m, 3,0 m and 6,0 m - Material: Aluminum die-casting |

| Maximum cable/hose outer diameter: | Ø 9,5 mm |

| Order no. | Bi [mm] |

Ba [mm] |

hi [mm] |

ha [mm] |

R [mm] |

||

|---|---|---|---|---|---|---|---|

| MF-10-50-075 | 1.97 | 2.48 | 0.79 | 1.08 | Upon request |

| further dimensions | |

|---|---|

| Installation height for the complete system: | 275 mm |

| Installation width of the complete system: | 107,6 mm |

| Recommended length of the trough sections: | Standard trough pieces 2 m length, anodised aluminium extruded profile |

| Maximum cable/hose outer diameter: | Ø 16 mm |

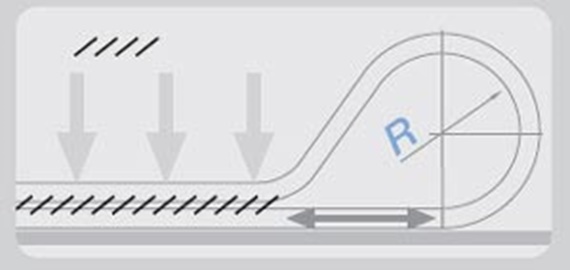

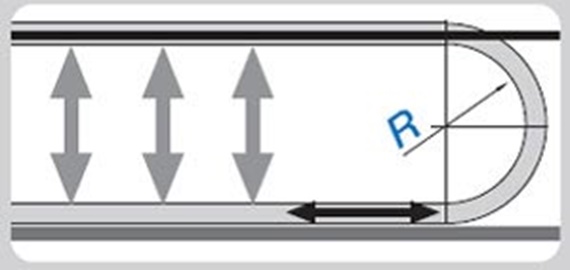

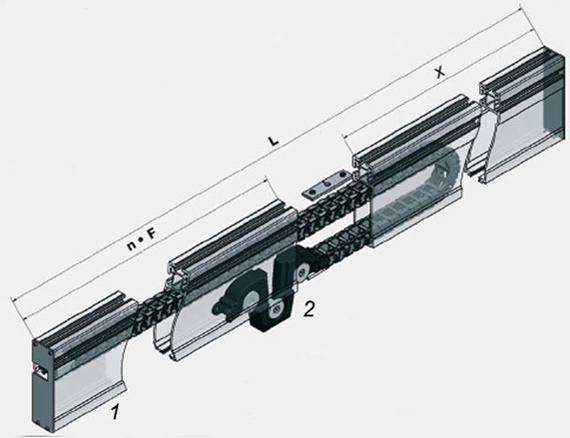

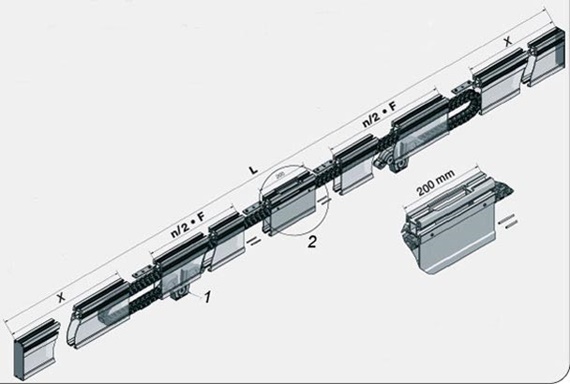

Separate upper and lower runs on the flizz® e-chain®,

hence less friction and reduced power consumption in motion

"Wings" firmly hold the e-chain® in the guide channel

3Plastic spring enables the e-chain® to roll softy in the flizz® channel, thereby significantly reducing the noise

4Integrated strain relief in the carriage for secure fixing of the cables

5Universal connection through three T-slots possible

6The e-chain® is fastened at the moving end via the moving end carriage

7Usable in the counter direction, which means double filling or two separate travels is possible