Strain-Relieving Core: The center core should be filled with a high-quality, high tensile strength core to protect the twisted conductors from falling into the center.

Conductor Structure: The copper stranding in chainflex® is chosen in accordance with tested and proven designs. igus®' test results indicate that a medium to fine strand diameter is preferable. Most typical flexing cable designs will employ an extra-fine conductor strand, and have a tendency to kink when subject to high-duty cycles. As a result of long-term testing, igus® uses a combination of single-wire diameter, pitch length and pitch direction to achieve the best flex life performance in even the most demanding applications.

Core Insulation: Insulation materials must be adhesion-resistant to one another within the cable. The insulation must also support the stranded individual wires of the conductor. Only the highest-quality, high-pressure-extruded PC or TPE materials should be used.

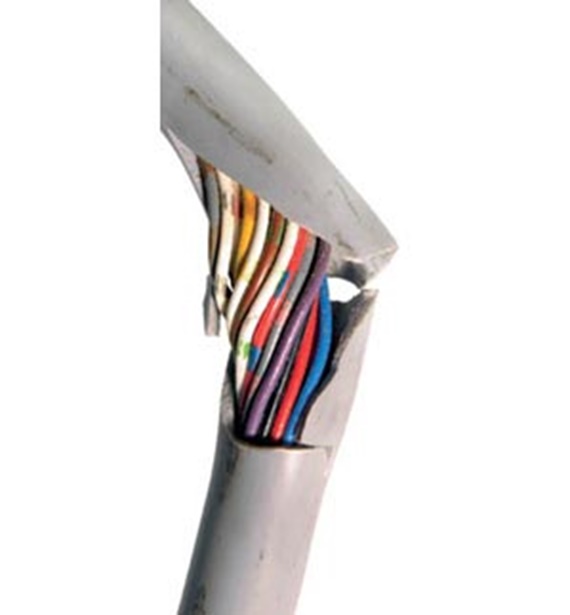

Cable Core: Individual conductors are bundled into groups. These bundles are cabled together in a single layer around the core. This design enables the pulling and compressing forces of the bending motion to balance and cancels torsional forces. Special attention is given to pitch length and pitch direction. The inner jacket will also maintain the integrity of the cable core and provide a continuous base for the shield.

Inner Jacket : A gusset-filling extruded inner jacket should be used instead of inexpensive fleece wrap or filler to ensure that the structure is efficiently guided in longitudinal direction. The inner jacket will also maintain the integrity of the cable core and provide a continuous base for the shield.

Shield Design: A high-quality braided shield protects cables from external interference and shields any interference before it is transmitted to the outside environment. An optimized braid angle prevents the shield strands from breaking over the linear axis and increases torsional stability. The shield has an optical coverage of approximately 90%, providing maximum shield effectiveness.

Outer Jacket: The outer jacket material must be UV resistant, abrasion resistant and resistant to oils and chemicals, as well as cost effective. However, it must not adhere to anything and be flexible while providing support. It should also be extruded under pressure (gusset-filled).