Inquiry / Contact

igus® inc.

| Part. No. TRC/TRE with | Length | max. | |

|---|---|---|---|

| mounted fiber rod lengths | ft | lbs/ft | |

| triflex® R 40 | |||

| TRC.F.40.1000.1.0 / TRE.F.40.1000.1.0 | 3.3 | 0.3 | |

| TRC.F.40.0900.1.0 / TRE.F.40.0900.1.0 | 3.0 | 0.3 | |

| TRC.F.40.0800.1.0 / TRE.F.40.0800.1.0 | 2.6 | 0.4 | |

| TRC.F.40.0700.1.0 / TRE.F.40.0700.1.0 | 2.3 | 0.5 | |

| TRC.F.40.0600.1.0 / TRE.F.40.0600.1.0 | 2.0 | 0.5 | |

| TRC.F.40.0500.1.0 / TRE.F.40.0500.1.0 | 1.6 | 0.6 | |

| TRC.F.40.0400.1.0 / TRE.F.40.0400.1.0 | 1.3 | 0.7 | |

| triflex® R 60 | |||

| TRC.F.60.1400.1.0 / TRE.F.60.1400.1.0 | 4.6 | 0.7 | |

| TRC.F.60.1200.1.0 / TRE.F.60.1200.1.0 | 3.9 | 0.8 | |

| TRC.F.60.1000.1.0 / TRE.F.60.1000.1.0 | 3.3 | 0.9 | |

| TRC.F.60.0800.1.0 / TRE.F.60.1800.1.0 | 2.6 | 1.1 | |

| TRC.F.60.0600.1.0 / TRE.F.60.1600.1.0 | 2.0 | 1.2 | |

| TRC.F.60.0400.1.0 / TRE.F.60.0400.1.0 | 1.3 | 1.3 | |

| triflex® R 70 | |||

| TRC.F.70.1800.1.0 / TRE.F.70.1800.1.0 | 5.9 | 0.9 | |

| TRC.F.70.1600.1.0 / TRE.F.70.1600.1.0 | 5.2 | 1.1 | |

| TRC.F.70.1400.1.0 / TRE.F.70.1400.1.0 | 4.6 | 1.2 | |

| TRC.F.70.1200.1.0 / TRE.F.70.1200.1.0 | 3.9 | 1.3 | |

| TRC.F.70.1000.1.0 / TRE.F.70.1000.1.0 | 3.3 | 1.5 | |

| TRC.F.70.0800.1.0 / TRE.F.70.0800.1.0 | 2.6 | 1.6 | |

| triflex® R 85 - in preparation | |||

| triflex® R 100 | |||

| TRC.F.100.2000.1.0 / TRE.F.100.2000.1.0 | 6.6 | 1.1 | |

| TRC.F.100.1800.1.0 / TRE.F.100.1800.1.0 | 5.9 | 1.3 | |

| TRC.F.100.1400.1.0 / TRE.F.100.1400.1.0 | 4.6 | 1.6 | |

| TRC.F.100.1200.1.0 / TRE.F.100.1200.1.0 | 3.9 | 1.7 | |

| TRC.F.100.1000.1.0 / TRE.F.100.1000.1.0 | 3.3 | 2.0 |

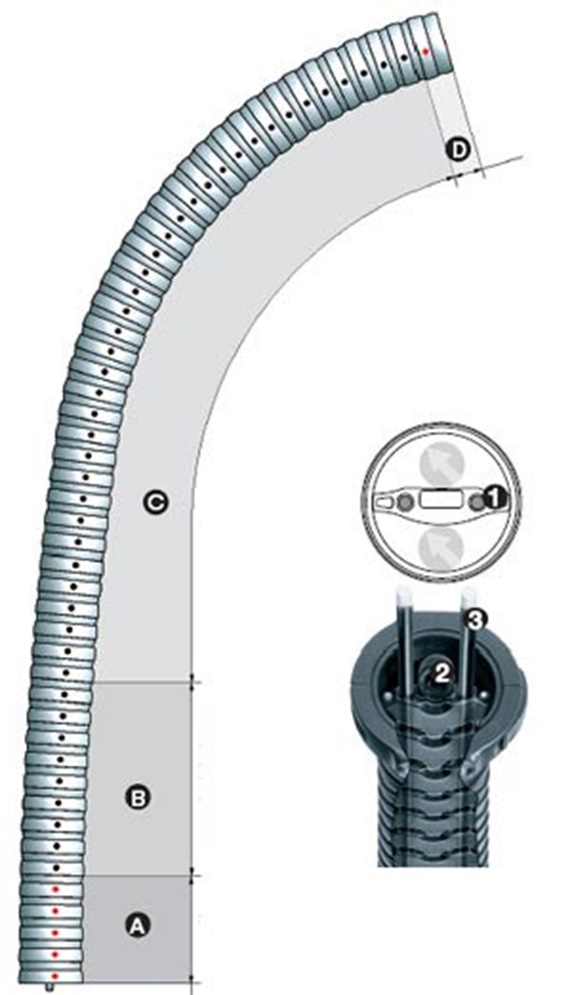

| For series | Max. |

|---|---|

| ft. (m) | |

| TRE/TRC.40 | 2.6 (0.8) |

| TRE/TRC.60 | 3.3 (1.0) |

| TRE/TRC.70 | 3.9 (1.2) |

| TRE/TRC.85 | 2.9 (1.2) |

| TRE/TRC.100 | 4.6 (1.4) |

Monday to Friday from 8 am - 8 pm

24h