Change Language :

Food-safe 3D printing for abrasion and wear-resistant parts

- Food-safe in accordance with the requirements of the FDA and/or EU directive 10/2011

- Up to 50 times more abrasion-resistant than commonly used 3D printing plastics

- No external lubrication needed thanks to integrated solid lubricants

- Replacement parts and special parts for speedy format change can be delivered overnight

* For express orders, please contact us by phone. Orders by phone or online for overnight manufacture must be submitted before 11 a.m. Normal manufacturing time: 1 to 3 business days.

Order abrasion-resistant parts from the 3D printing service or print them yourself

Upload 3D model as STEP file and get prices without any commitment to buy

Laser sintering for compliance with food-specific regulations

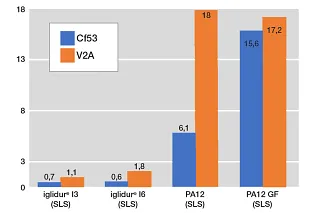

Rotating wear: p = 1 MPa; v = 0.3m/s

The laser sintering material iglide i6 complies with the food-specific regulations of the FDA and of EU 10/2011 and can therefore be used in numerous applications in the food and beverage industry. Due to the SLS method, special parts, prototypes and volumes can be made in our undefined in quantities from 1 to 10,000 in only 3 days. Out of all the 3D printing materials that are processed by igus and are compliant with food-specific regulations, iglide i6 is chosen the most frequently. This is due to the greater strength, better surface and lower component price.

The component materials of iglide i6 make this high-performance polymer not only especially hygienic but also especially capable of sliding. It is therefore often requested for applications in which an especially low degree of friction is required, for example worm wheels. The SLS powder can be purchased in our shop and processed with all regular laser sintering equipment.

Making food-safe components yourself

iglide I150 is the easiest to process tribo-filament® - it is suitable for all commercially available 3D printers and can be processed just as easily as regular filaments such as PLA and PETG. Thanks to compliance with EU 10/2011, iglide I150 is suitable for contact with food and is accordingly proving itself in applications in the food and packaging industry. The only restrictions are in the maximum permanent application temperature of 65°C and for highly dynamic applications. iglide I150 is also available on 8kg filament reels and is therefore suitable for the manufacture of large components in large-scale printers.

Heat-resistant and food-safe

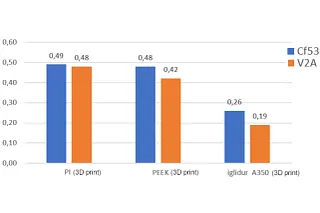

Rotating coefficient of friction, p= 1MPa, v= 0.3m/s Vertical axis: Coefficient of friction [-]

The abrasion-resistant high-temperature tribo-filament® iglide A350 was specially developed for the food and packaging industry. The raw material is compliant with EU 10/2011 and FDA food-contact regulations and is blue all the way through for reasons of detectability. Printed parts made of iglide A350 are temperature-resistant up to 180°C, are flame-retardant in accordance with UL94-V0 and can also be sterilized with hot steam. Due to its high processing temperature of 340-360°C as well as a mandatory build chamber temperature of min. 160°C, a high-temperature 3D printer is required for processing. If no such a printer is available for use, wear-resistant parts made of iglide A350 can be manufactured quickly and cost-effectively in the igus undefined.

Further solutions for food contact

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert