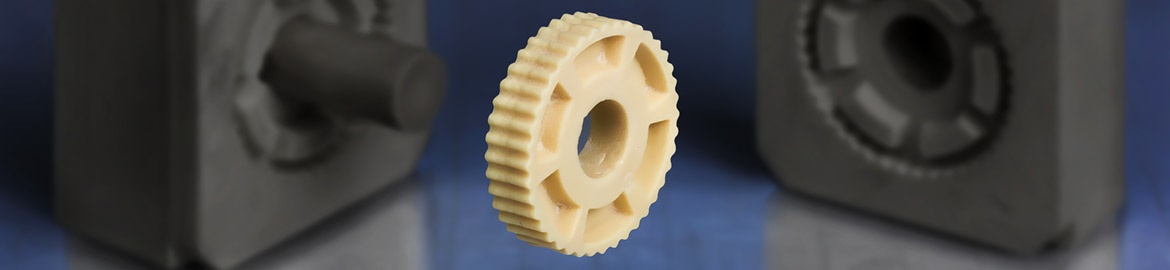

3D-printed injection molds are

cost-effective & can be custom-made

cost-effective & can be custom-made

Our 3D-printed injection molds produce parts with similar material properties as components from conventional serial molds. With print2mold, igus® 3D prints injection mold tooling out of our engineered composite plastic iglide® materials, which are up to 80% cheaper than steel materials. We extensively test the tribological properties of our plastics inside our 41,000-square-foot lab in Cologne, Germany to ensure each material offers a longer service life than standard 3D-printing materials. All iglide® materials are low-wear, self-lubricating and maintenance-free. More than 50 iglide® plastics are available for printing injection molds.

- Up to 80% cheaper than steel materials

- Up to 70% faster than manufacturing conventional tooling

- Fast and simple production of prototypes

- Choose between 55 low-wear iglide® materials

- Maintenance-free components with special properties, such as conductivity, underwater use, KTW conformity, high temperature, etc.

Upload a 3D model (STL/STEP). Select material, printing method and get pricing.

► Upload not working? Click here to start the upload directly in the 3D printing service tool.

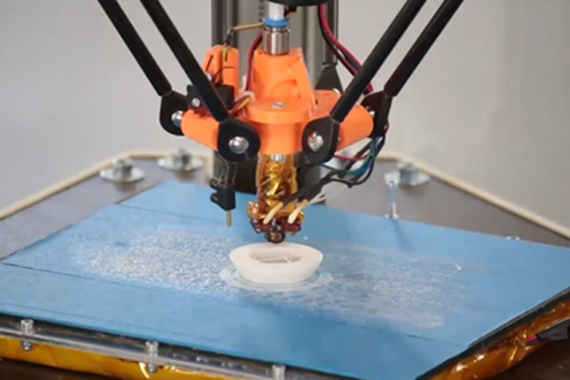

3D-printed injection molds vs. 3D printing

3D printing your components directly is a better option if you need them delivered between 24 hours and three days or if they have a complex design. There is no additional charge for complexity since 3D printing is a tool-less manufacturing process. Directly printing small parts under 5g, whether simple or complex, could also be more cost-effective than injection molding. igus® offers an online 3D printing service so you can easily order custom-made parts and receive them quickly. Our high-performance iglide® materials are also available as filaments for 3D-printing and are well-suited for moving applications due to their high abrasion resistance and excellent coefficients of friction.

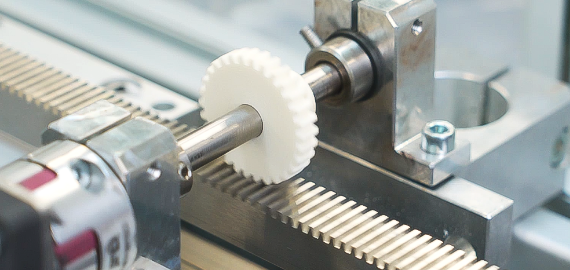

3D-printing materials test lab

Our 3D-printed injection molds produce parts with similar material properties as components from conventional serial molds. That’s because we extensively test the tribological properties of our iglide® plastics inside our 41,000-square foot lab in Cologne, Germany. This ensures that each part made from our materials will offer a longer service life than standard 3D-printing materials.

Advantages of iglide® materials

- 100% dry-running and maintenance-free

- 100% corrosion-resistant

- 80% weight saving compared to metal

- Precisely predictable service life

- Tested in the industry's largest test laboratory under realistic application conditions

Discuss your project with a custom parts expert

Whether you're interested in end-to-end, fully assembled solutions or looking to build your own customizable project, learn more about how igus® can assist you with a solution based on your specific application and requirements. Contact us via the form below or call us at (800) 521-2747 to discuss your project today!