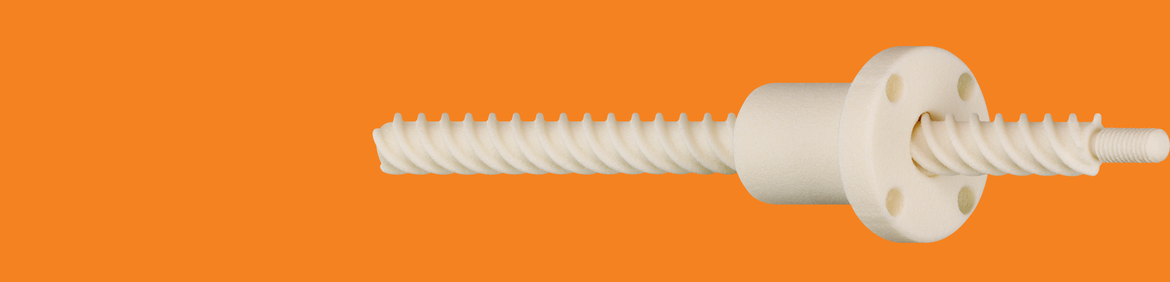

3D-printed lead screw nuts and drive nuts

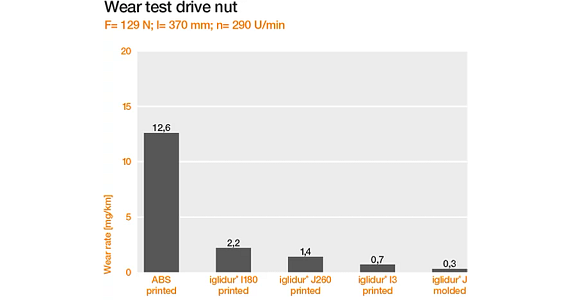

Our 3D-printed lead screw nuts and drive nuts are created using our engineered composite plastic iglide® printing materials, which have been proven to last up to 50 times longer inside moving applications than standard 3D-printing materials. igus® engineers extensively test our iglide® plastics inside our 41,000-square-foot test lab based in Cologne, Germany to ensure that every 3D-printed component offers exceptional wear resistance comparable to injection-molded components. All igus® 3D-printed parts are low-friction, maintenance-free and self-lubricating. Metric and trapezoidal threads can be printed directly on the component from size M6 to TR6.

Benefits:

- Various special iglide® polymers available for moving applications

- 3D-printed parts with wear resistance comparable to injection-molded components or bar stock

- Rapid production – even for complex parts

- Easily upload and order your CAD file online

- Necessary component adaptations and optimizations possible

- Prototypes, special components and small batches – no minimum order quantity required!

Browse the Shop

Browse our Materials

Shop all of our 3D printing materials below. To learn more about our materials, the testing process, etc. click here.

SLS Powder Material

- High wear resistance and great strength for sliding applications and gears

- Best seller in 3D printing service

- Can be processed with suitable commercially available laser sintering machines

Browse the Shop

FDM Filament

- Materials for special requirements such as FDA, high-temperature & chemical resistance

- 1.75mm and 3mm diameters

- High wear-resistance

- Low coefficients of friction

Browse the Shop

DLP Resin

- World's first wear-resistant DLP resin

- 30-60x longer service life compared to conventional 3D printing resins

- Gears with the tooth module of 0.2 possible

- High level of detail: resolution up to 35 μm

Browse the Shop

3D Printing Service

Our 3D-printing service uses powders and filaments that have been proven to last up to 50 times longer than standard 3D-printing materials inside moving applications. All igus® 3D printed wear parts are low-friction, maintenance-free and self-lubricating.

Use the 3D Printing Service

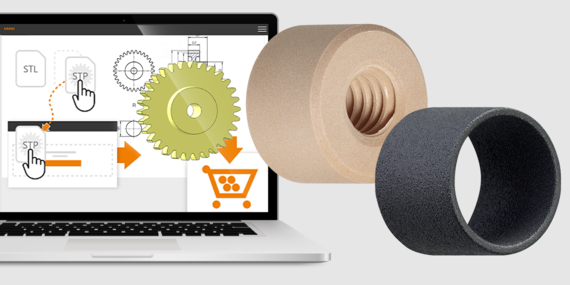

CAD Configurator

This tool allows users to download CAD files for 3D printed bearings, gears, rollers and bar stock. Views of components appear in both 2D and 3D, and detailed product information is available. Individual designs can also be easily uploaded and configured.

Use the CAD Configurator

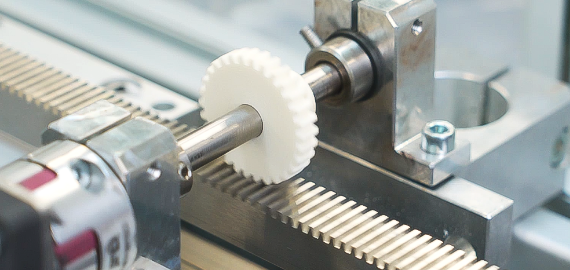

View our 3D printing test lab

igus® engineers extensively test the tribological properties of our engineered composite plastics inside our 41,000-square-foot test lab to ensure every 3D-printed part will last 50 times longer than typical 3D-printing materials inside moving applications.View the 3D printing test lab

Discuss your project with a 3D Printing expert

Whether you're interested in turnkey, fully assembled solutions or looking to build your own customizable project, learn more about how igus® can assist you with a solution based on your specific application and requirements. Contact us via the form below or call us at (800) 521-2747 to discuss your project today!Contact an Expert