Tool guide system

Filling process

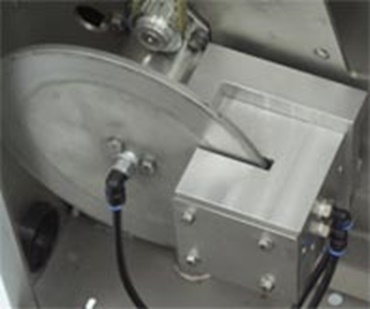

Film welding unit

Guides for the deep drawing process

No lubricants at the products

Maintenance-free solution

Wear-resistant solution in spite of cleaning process

Dirt accumulation

Fastest demounting of bearing

Cost advantage

Cleaning with hydrogen peroxide possible

Dirt accumulation possible

Cleaning with hydrogen peroxide

Recirculating ball bearing is no alternative (cleaning)

Cost saving

Combination with soft

Stainless steels possible

Maintenance-free

Wear-resistant solution in spite of cleaning process

No washing-out of the lubrication

No corrosion of the ball (soft stainless steel ball instead of hardened ball)

Lower adhesion factor, than bush bearing

Resistant against chemicals

Cost advantage

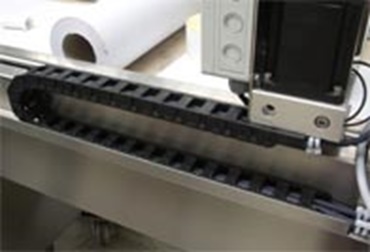

Easy to install through split bearing housing

No rinsing of the recirculating ball bearings

Good corrosion-resistance

Vibrations during punching have no influence on the shaft

For this reason: No shake down of the shaft

Cost saving

Combination with soft stainless steel shafts

Maintenance-free solution

No impact from dirt accumulation through punching waste