The use of plastic plain bearings facilitates 8 x longer service life

Test results for St52 / gas nitrified

In an effort to continuously improve our product range and to address your specific needs, we are reviewing various shaft materials and extensively testing these with a variety of bearing solutions in our igus® dry-tech® lab.You can find the results for our test results for St52 / gas nitrified here.

We are currently also conducting tests on the following shafts / coatings:

St52 / un-coated

C45 / un-coated

Piston rods / hard-chromed

St52 / salt bath nitro carbonized

C45 / galvanized

Test Report (PDF)

Wear in μ/km; p= 4,351 psi; v= 0.0328 ft/s; pivoting

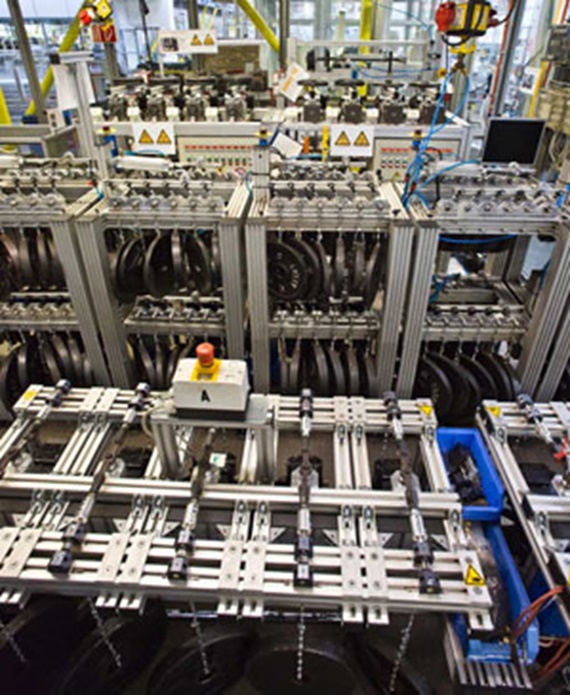

dry-tech® test laboratory

1

Wear rate [μm/km]

2iglide® Q

3iglide® G300

4iglide® Z

5Brass with initial lubrication

6Rolled metal with gliding layer

Conclusion:

all tested iglide® materials exhibit significantly lower wear than metal plain bearings

the shafts of the metal plain bearings exhibit significant wear and are therefore unsuited for further use

Is your shaft not included in these?

We will gladly test your specific application as well. Simply use the contact form!Contact us!