- Installation size: NEMA23/flange dimension 56mm

- Protection class: IP65

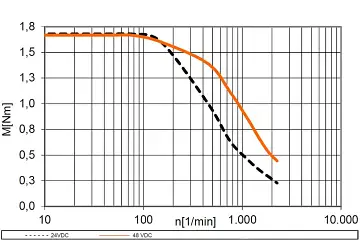

- Holding torque: 2.00Nm

- Nominal current: 4.20A

- Motor connection: connection cable 1m

- Shaft seal prevents ingress of water

drylin® E stepper motor, connection cable, NEMA23

The most popular stepper motor size

The stepper motor features high torque and compact dimensions. It is perfect for a number of applications in the medium load range. The stepper motor works precisely, is robust, cost-effective and easy to control. Its application areas are inexpensive stand-alone devices, as well as automation machines and format adjustments. The motor connection here is a cable with an open stranded wire. This protrudes 1m from the rear part of the motor housing. The advantage of this connector is that it is more cost-effective than the metric connector. To ensure that not only the housing has an IP65 protection rating, this motor has also been equipped with a shaft seal. Therefore, the complete motor has an IP65 classification.