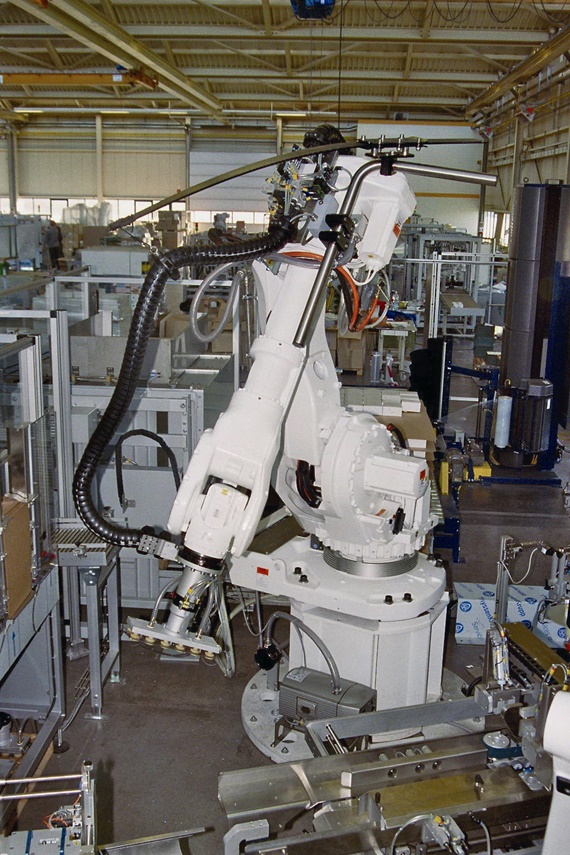

Cable carrier for palletizing robot

Robot uses complex movements

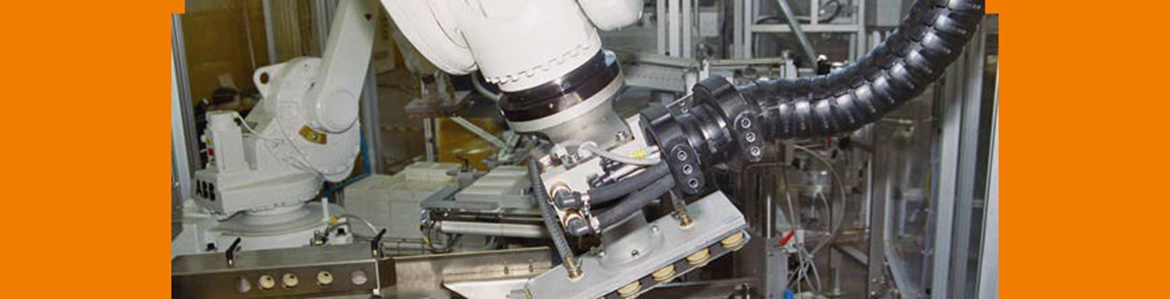

This packaging system processes up to 17 different formats at high speeds. Up to 350 glass bottles filled with pharmaceutical drugs can be packed into cartons every minute.Several monitoring stations, some involving camera systems, are integrated into this production line to detect irregularities. The robot places the carton on one of these stations.

Multi-axis guidance

The design engineers responsible for this system decided a triflex® R cable carrier should guide the vacuum cable and control cables for the robot’s gripper.To optimize the motion sequences of the cable carrier, a tube angled at 90° is mounted on the fastening points of the robot and a spring element is mounted onto this tube. The requisite pullback movements are initiated over a cord connection between the spring module extension and the triflex® R. The multi-axis movement of the cable carrier is guided over the position of the fastening tube and loop formations are thereby avoided at the robot's wrist, as well as friction against the robotic arm.

More product information

More application examples from different industries

Cable carrier applications