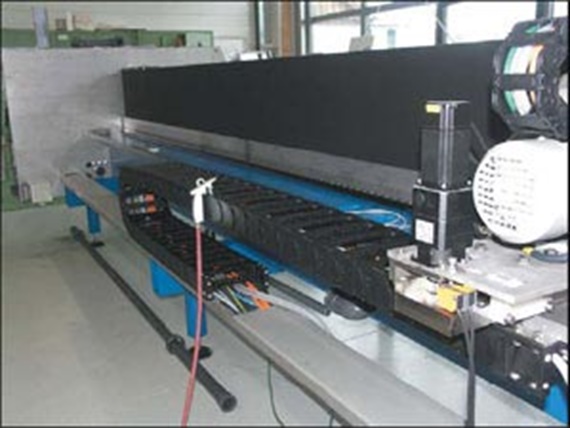

High precision turning-and-grinding machine

Operating for 9+ years in harsh environment

For at least 15 years, one company has been using various cable carrier systems from igus®, including both open and closed styles.

The company recently replaced a turning-and-grinding machine after nine years and, in the general overhaul, it was discovered that the igus® cable carrier systems were still in impeccable condition, despite the harsh environment in which they'd been operating.

The cable carrier system consisted of fully pre-assembled Series 38 and 39 cable carriers and chainflex® continuous-flex cables.

The company recently replaced a turning-and-grinding machine after nine years and, in the general overhaul, it was discovered that the igus® cable carrier systems were still in impeccable condition, despite the harsh environment in which they'd been operating.

The cable carrier system consisted of fully pre-assembled Series 38 and 39 cable carriers and chainflex® continuous-flex cables.

Machining center uses 7 x cable carriers

The company uses seven cable carrier systems in the machining center, of which two are fully pre-assembled readychains®. Six move the axles and one is responsible for supplying the control cabinet.

The speed of the tool shaft is about 29.5 feet per minute, and the length of travel around 8.2 feet total.

The cable carrier systems operate under high mechanical stress during an uninterrupted, three-shift operation, seven days a week.

The speed of the tool shaft is about 29.5 feet per minute, and the length of travel around 8.2 feet total.

The cable carrier systems operate under high mechanical stress during an uninterrupted, three-shift operation, seven days a week.

Useful links

More application examples from different industries

Cable carrier applications