Manual, Propelled and Automated Format Adjustments for the Packaging Industry

In the packaging, food and beverage industries, the demands on flexibility of modern production systems continue to increase. Large variance in product diversity as well as decreasing batch sizes increasingly put optimal plant availability up for discussion. The resulting shortened set-up times, for example when changing formats, are increasingly becoming standard requirements in the packaging industry. Product and size-dependent adjustments of inlet lanes, format changes in film feed correction and sealing tools, positioning of labelling stations or fine adjustment of sensors are just a few examples.

Manual

Linear guides with manual clamp- For easy format adjustments

- Maintenance-free, no lubrication

- Individual clearance adjustment

Learn more

Propelled

Linear actuators driven by hand wheel- For precise positioning tasks

- Highly torsion-resistant and bend-resistant

- Different shaft and lead screw materials

Learn more

Automation

Linear actuators with motor and control system- For coordinated adjustments of multiple axes

- Electrically adjustable with position feedback

- Broad portfolio of linear systems and motors

Learn more

Manual

Area of use

If simple and rarely performed adjustment tasks are to be implemented in packaging machines, linear rail systems with simple positioning by hand wheel are often suitable.Configure linear bearings

With the linear guides configurator, you can assemble your individual linear system in just a few steps and calculate the service life at the same time.Use the Configurator

Browse the Shop

Linear rails with manual clamp

- With absolutely self-lubricating and maintenance-free liners

- Wide range of modular systems

Browse the Shop

T-rails with manual clamp

- Easy handling, maintenance-free in use

- Robust and corrosion-resistant rail guides

Browse the Shop

Square guide with manual clamp

- Flexible linear square guides

- With robust and lightweight aluminum profile thanks to the hollow chamber principle

Browse the Shop

Low-profile guide system with manual clamp

- Flat guide rails for small installation spaces

- Maintenance-free dry operation and low wear

Browse the Shop

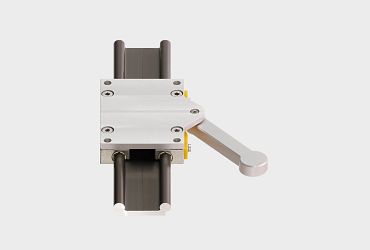

Linear carriage with manual clamp

- Linear carriage with integrated manual clamp

- Secure handling and quiet clamping

Browse the Shop

Shaft guide with manual clamp

- Carriage with manual clamp for linear bearings with shaft guides

- With anodised aluminum housing

Browse the Shop

User report

Filling level device of folding and gluing machine

In the transverse adjustment of the filling level device of this cartoner, a maintenance-free drylin W linear guide with manual clamp allows a weight-optimized and wear-resistant construction.

Propelled

Area of use

Demanding format adjustments are carried out with flexurally rigid linear axes. A hand wheel allows manual adjustment and a position indicator allows fine adjustment of a desired control value.Configuring the drive

With the linear actuator configurator, you can put together your desired linear system individually and select from a wide range of product solutions.Use the configurator

Rail-based linear actuators

- Torsion-resistant aluminium double shaft profiles

- Trapezoidal lead screws & linear rails

- With manual clamp and position indicator

Browse the Shop

Linear actuators with double shafts

- Individual configuration of shaft and lead screw materials and carriage lengths

- Completely self-lubricating adjustment

Browse the Shop

Flat lead screw linear actuators

- Extremely flat design with lateral lead screw arrangement

- Self-lubricating and maintenance-free

Browse the Shop

Linear actuators, 2 lead screws

- SLW linear actuator with double lead screw and carriage

- Wide load-bearing surface and high flexibility in the design of the drive

Browse the Shop

Compact lead screw linear actuator

- Designed for confined installation spaces

- Extremely light and quiet yet robust at the same time

Browse the Shop

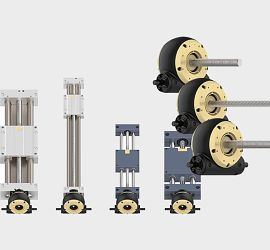

Angular gearbox/ Bevel Gears

- Lightweight housing

- Corrosion and self-lubricating

- Ratio 1:1 to 1:5 available

Browse the Shop

User report

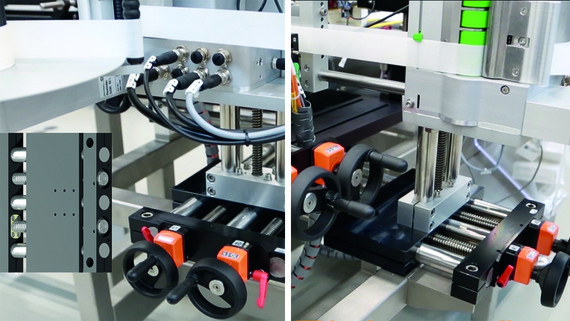

Page and format adjustment for folding boxes

In this testing and packaging system from the manufacturer Wipotec, flexurally rigid drylin linear systems with manual adjustment are used in several places. Side and format adjustment for various folding box dimensions is ensured via the linear axes, as is the adjustment and fine adjustment of sensors.

Automation

Area of use

Recurring format adjustments are carried out efficiently using a stepper motor. And with the optional addition of a motor control system, several adjustment units can be positioned at the same time.Configure the Drive

In the linear actuator configurator, you can put together your desired linear system individually and select from a wide range of product solutions.Use the Configurator

Browse the Shop

Linear actuators with stepper motors

- Powerful stepper motors with anti-rotation feature

- Find the right drive for your application with the product finder

Linear actuators with motor control system

- Control system to determine travels, positions, speeds and loading times.

- Quick commissioning, intuitive user interface

Apiro synchronizing gearbox

- Modular gearbox kit for synchronising multiple adjustments

- For modular and cost-effective automation

Angular gearbox for synchronization

- Lightweight housing

- Corrosion and self-lubricating

- Ratio 1:1 to 1:5 available

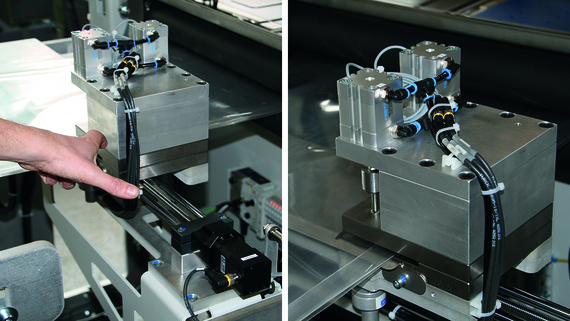

User report

Automated format adjustments in film packers

This packaging machine consistently relies on automation for greater operational safety and a modular concept. The linear systems for positioning the hole punch, adjustment of the filling station and format adjustment of the labeller were supplemented by stepper motors.