e-chains® successfully replace trailing

cables on bridge cranes in concrete plant

With the two gantry cranes, which at Beton Kemmler GmbH travel on the same rails mounted on the longitudinal side of the hall, the entire pipe production is largely fully automated. Until 1993 the cranes were supplied with power and controlled via trailing cables.Profile

- What was needed: readychain® harnessed energy chain

- Requirements: Reliable complete system that supplies the cranes with a constant power supply. Easily openable, tough system that withstands external conditions, reliable operation

- Industry: gantry cranes

- Success for the customer: With a completely pre-assembled system from igus®, the installation times were kept short and a longer production downtime was avoided.

Contact an igus® expert now

The challenge

"In the rough environment inside a company that works with concrete, energy supply systems have been making a decisive contribution towards the stability and functional reliability of the indoor cranes and linear robots. In the huge production, drying and storage hall, two overhead cranes equipped with gripper robots must be supplied with energy.Until 1993 the cranes were supplied with power and controlled via trailing cables. However, incidents have repeatedly occurred during this process. At more or less regular intervals, the towing carriages got caught in their running rails, which not only brought the entire system to a standstill, but often led to longer-term and cost-intensive repair times due to ruptured cables.

readychain® Pre-Assembled Cable Carriers with Cable

Solution

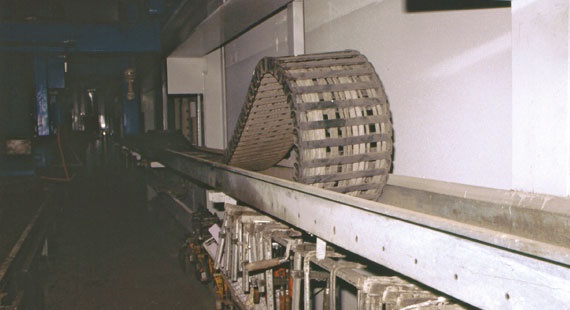

In the concrete pipe production, an energy supply system was installed several years ago, which not only reduced downtimes to a minimum, but also set new standards for the power supply within the Kemmler plant in general.For many years now, the system with energy chains of the proven Series 50 has been operating virtually flawlessly and has since covered a distance of approx. 6.6 million meters. The energy chain series convinced by the crossbars openable from both sides and useful accessories, such as diverse interior separation and integrated strain relief.

In the course of preventive maintenance measures, the energy supply systems were replaced. Special plastics and the special design of the chain joints give the igus products a mechanical stability that is otherwise only achieved by metal chains.

By supplying harnessed energy supply systems, so-called readychain® systems, igus® offers a solution in which all power and control cables are already inserted during chain assembly (according to the user's specifications).

Another important advantage of the readychain® is that cables from our own tested chainflex® range are used. Due to the cores wound in bundles, the gusset-filling extruded inner jacket and the outer jacket material — which is optimally matched to the use in the energy chains — the flexibility of these cables can be optimally adapted to the application-dependent bend radius of the energy chains.

Another important advantage of the readychain® is that cables from our own tested chainflex® range are used. Due to the cores wound in bundles, the gusset-filling extruded inner jacket and the outer jacket material — which is optimally matched to the use in the energy chains — the flexibility of these cables can be optimally adapted to the application-dependent bend radius of the energy chains.