iglide® F3 material is now also available for rollers. When electrical conductivity is important and electrostatic charging of the components is to be avoided, iglide® F3 is exactly the right choice. As the material contains incorporated solid lubricants, the rollers can be used without any additional lubricants and the maintenance associated with them. The use of ball bearings is therefore not necessary.

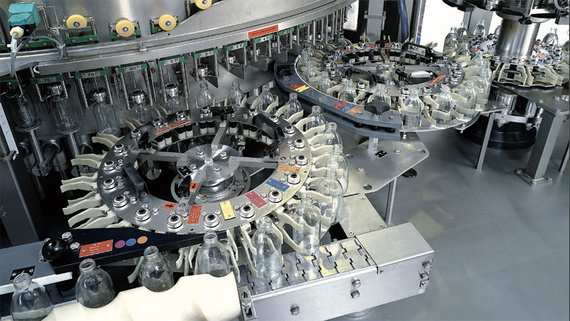

For this beverage bottling line, Krones AG was looking for wear-resistant rollers that would ensure a functioning system in the long term. The rollers used so far could not withstand the high cycle rates and the work in three-shift operation. "Earlier the rollers in particular wore out too quickly, so that the customer had to overhaul the clamping star wheel relatively frequently [...]. Here there was an urgent need for action. We have now eliminated this weakness." Jürgen Steimmer, Group Manager Labelling Technology, Krones AG.

Krones AG found the solution in igus® polymer rollers. They consist of a polymer sleeve provided with an outer jacket made of TPU. Here, the iglide® material shows why it is a good choice, mainly due to its wear resistance. The outer jacket provides good grip on the outer component so that the bearing is always carried along. Accordingly, only the polymer sleeve made of iglide® wears out. The service life could almost be doubled with the iglide® rollers.

Monday to Friday from 8 am - 8 pm

24h