Steering linkages & linear slides for automotive

drylin® linear bearings are engineered to slide with high-performance, self-lubricating plastics which are maintenance-free and offer consistent coefficients of friction. For automotive applications they offer lightweight, clean, quiet, and vibration-damping operation.

Shop dry-tech® linkages, linear guides & other parts for automotive

drylin® bearing liners

- For all shaft materials

- Application temperature: -58 to +194°F

- Best coefficient of friction with steel shaft

- Longest service life with aluminum, hard-anodized

drylin® lead screws

- High helix, trapezoidal, metric and ACME sizes

- Dry operation

- Lightweight

- Quiet operation

igubal® steering linkage systems

- Custom solutions available

- Vibration damping

- Easy assembly

- Custom lengths available

igubal® special solutions

- low-cost

- fast delivery

- spherical balls available in different iglide® materials

- maintenance-free

Examples of dry-tech® products in onboard use

Resistant to heat and dirt

The self-lubricating properties of drylin® linear guides allow for sliding motion and are resistant to dirt and high temperatures. They are corrosion-resistant and they show very low moisture absorption.

Quiet operation and maintenance-free

drylin® linear guides are designed for smooth and quiet operation based on their high-performance polymer components which are self-lubricating and maintenance-free.

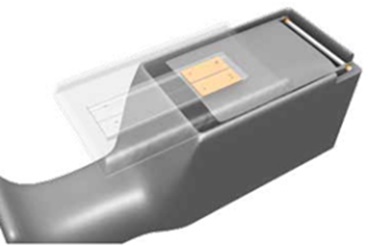

Easy and safe adjustment of head rest

The durable drylin® material is maintenance-free and has a long service life. Due to its design, the head rest can be adjusted conveniently.

Custom-made components for very high temperatures

The self-lubricating properties of drylin® linear guides allow for sliding motion and can tolerate very high temperatures. They are corrosion-resistant and show very low moisture absorption.

Steering linkages for gear applications

igubal® steering linkages replace their metal counterparts in gear box applications as the high performance polymers reduce noise and are vibration damping.

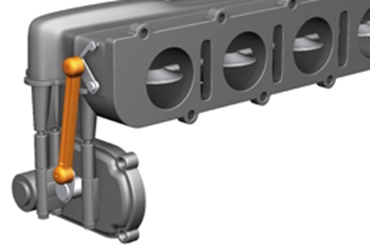

Custom linkage joints for controlled intake manifold

The advantages of igubal® polymer linkage joints are a high load bearing capacity and a significant reduction in weight as well as wear rate. These properties make them superior to their metal counterparts.

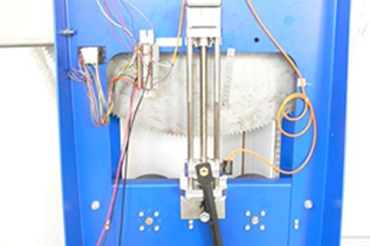

dry-tech® products used in automotive production

Reduced maintenance in painting processes

Replacing actuators with igus® products made of high-performance polymers not only reduces maintenance significantly, it also eliminates the need for lubrication.

Continuous operation and easy assembly

When cleaning and laser marking axle shafts, drylin® linear guide systems have proven to facilitate processes significantly as they are easily installed and do not require any maintenance.

A long service life despite harsh environmental conditions

During spot-welding processes, components are required that can withstand the rough working conditions. drylin® linear guide systems have proven to be unaffected by these circumstances.