Self-lubricating

Maintenance-free

For application in extremely dirty environments

For underwater or washdown applications

Compensation of misalignments

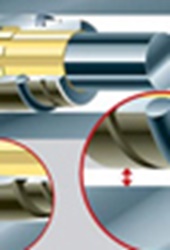

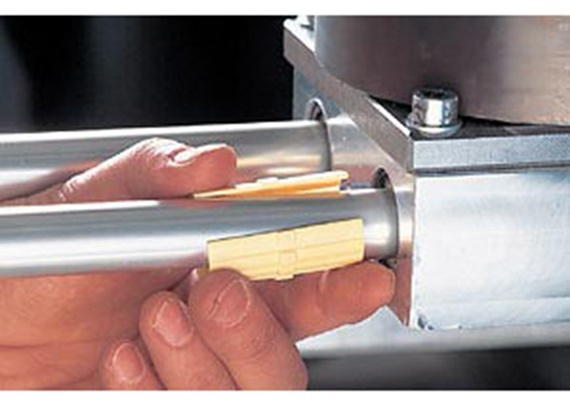

Simple insertion and replacement of the liners

Dimensions compatible with standard ball bearings

Vibration dampening

No need of seals or wipers

1. More robust bearing thickness offers longer lifetime Less potential for downtime or replacement costs. Metal-on-metal contact is avoided.

2. Easy-to-replace liner for lower overall costs No scrap aluminum to waste. The liners can also be used alone without the aluminum housing.

3. Lower cost Up to 25% savings possible.

4. drylin® Expert System Exclusive lifetime calculation program.

5. Integrated dirt channels Better performance in aggressive environments.

6. RJI / RJM all-polymer parts available Superior corrosion resistance, low weight, and lower cost.

1. Self-lubricating Reduced maintenance and downtime costs. No messy oil or grease to handle.

2. No oil More suited to sensitive environments: laboratory / food / pharmaceutical / packaging / air.

3. Lower cost Savings of up to 60% in some cases, not to mention reduced maintenance costs.

4. Better for dirty environments due to patented dirt channels and dry-running characteristics. No oil to attract dirt, dust, or debris into the system and a more consistent coefficient of friction.

5. Higher accelerations possible Since drylin® R uses a one piece sliding film, instead of recirculating balls, unlimited accelerations are possible without damaging the shafts.

6. Higher static load and better vibration dampening characteristicsPoint-to-point contact is avoided by using the greater surface area of the iglide® J thermoplastic liner.

7. Lighter weight and more compact designs possibleSince the liners are so small, they can be integrated into your designs without the bulk of a recirculating ball bearing. This makes them ideal for aircraft interiors, furniture, and more.