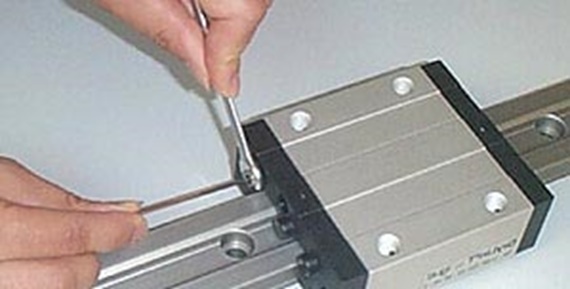

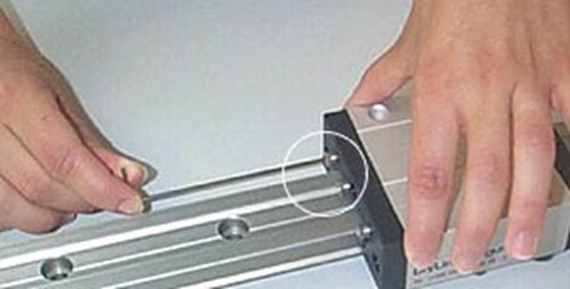

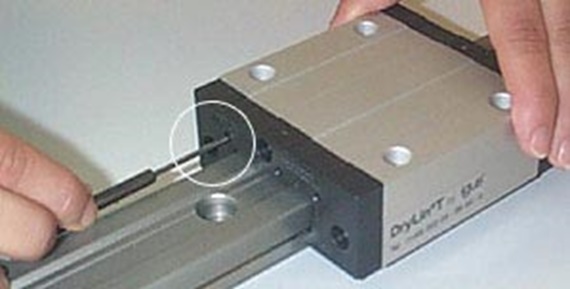

drylin® T: Adjusting the clearance

drylin® T linear guides are delivered with a pre-adjusted clearance ready for installation. This pre-adjustment is determined by the acting forces on each individual system. If you have special requirements, please indicate in your order whether particularly limited or extended bearing clearance is required. If necessary, the clearance of the drylin® T linear guide system can also be re-adjusted later. This should always take place when there is no load on the carriage.

SW 5 for TW-01-15 and TW-01-20

SW 7 for TW-01-25 and TW-01-30

0.06" (1.5 mm) for TW-01-15 and TW-01-20

0.08" (2 mm) for TW-01-25 and TW-01-30

0.06” (1.5 mm) for TW-01-20 and TW-01-15

0.12” (3 mm) for TW-01-25

0.12” (3 mm) for TW-01-30