Change now and reduce your costs by up to 40% with drylin® linear bearings

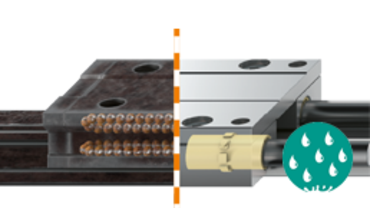

Only sliding elements made of optimized drylin® high-performance plastics are used for our moving applications. Therefore, self-lubricating drylin® linear solutions can replace metallic recirculating ball bearing systems in almost all areas of use and cut up to 40% of the costs! Learn more about our wide range of linear bearings and slides here.

Benefits:

- Up to 40% more cost-effective than recirculating ball bearing guides

- 100% self-lubricating and maintenance-free

- Corrosion resistant and hygienic

- Wear-resistant

- Resistant to dirt, dust and humidity

- Extremely quiet operation

- No minimum order value, no minimum order quantity

- Shipped within 24-48 hours

- Service life can be calculated online

Use the Linear Guide Expert Configurator

The advantages in detail

High performance polymers make drylin® linear technology even more durable

Due to the use of sliding elements made with high performance polymers, drylin® linear technology is extremely wear-resistant and durable, even when subjected to high mechanical loads.

Customer application:

acquiring an edge with drylin®

Both precision and durable linear guidance are achieved with drylin® linear drives. The NOVASPORT grinding machine (see above on the right) creates an edge without any loss of required precision.

Find out more

Want to find out more?

drylin® linear bearing systems are durable under various environmental conditions—they withstand dirt, humidity and liquids, high and low temperatures, severe vibrations, and hard shocks and knocks.Find out more

drylin® linear technology – long service life regardless of significant exposure to dirt

Unlike recirculating ball bearing guides, drylin® linear technology uses sliding elements made of high-performance polymers that prevent dirt and dust from adhering.

Customer application:

Free from dirt and dust

The mobile saw mill of Serra Maschinenbau GmBH was developed to be low-maintenance and easy to operate, regardless of harsh environmental conditions. Dirt-resistant drylin® linear technology helps the saw mill reach these requirements.

Want to find out more?

drylin® can be used in places where sand, chips and dust are present—the contact surface between the plastic sliding element and the guide simply forces foreign bodies out of the way, similar to the way a snow plough functions.Find out more

No corrosion, no grease – drylin® linear technology

The materials used in drylin® linear guides are highly resistant to various media and have been tested for use under water.

Customer application: labeling without rust

Particularly in the food and beverage industry, certain hygiene requirements have to be met. To reach the requirements, machines and components must be corrosion-resistant, as in the case of this labelling machine.Want to find out more?

The combination of highly alloyed stainless steel (e.g. 1.4571) with a high-performance polymer (e.g. iglidur® X) is resistant, even when it comes in contact with seawater.Find out more

Save up to 75% in weight with drylin® linear technology

Conventional recirculating ball bearing guides mainly consist of metal, while drylin® linear technology is made of lightweight, high-performance polymers.

Customer application:

Drone - Light and easy guidance

A drylin® guide made of carbon fibre was used for a drone – The guide has the necessary stability while being robust and extremely light.

Find out more

Want to find out more?

drylin® linear bearing systems are designed for low-height installation dimensions and low weight. The use of sliding elements made of plastic guarantees low mass for easy handling.Find out more

Four times quieter due to polymer sliding elements

Thanks to their sliding elements, drylin® products made of high performance polymers have a noise output of 20 dB on average and are therefore around 4 times quieter than corresponding linear bearings made of metal.Want to find out more?

drylin® linear bearing systems slide on plastic instead of rolling on steel balls. As a result, significantly less noise and vibration is generated.Find out more

Self-lubricating linear technology for extremely demanding hygiene requirements

Due to self-lubricating sliding elements and a linear bearing liner made of high-performance polymers, drylin® linear technology is exceptionally clean and hygienic.

Customer application:

clean pipetting

A clean linear guide that meets the challenging hygiene and precision requirements in the pharmaceutical, biological, chemical and medical industries is essential for pipetting devices used by the University of Ljubljana.

Find out more

Want to find out more?

All drylin® linear bearing systems operate without any external lubrication such as oil or grease and are therefore extremely clean. In cleanrooms, splashed grease and oil mist can be ruled out completely.Find out more

Plain bearings vs. rolling bearings comparison

Properties | Characteristics of igus® plan bearings | Characteristics of rolling bearings | Technical data of igus® plain bearings | Technical data of rolling bearings | Especially relevant for the following industries: |

|---|---|---|---|---|---|

| Precision | + | +++ | 0.02 - 0.15 mm | 0.001 - 0.01 mm | Machine tools, CNC processing, electronics manufacturing |

| Completely lubrication-free | +++ | + | Medicine, packaging, food, cleanroom, consumer goods | ||

| Maintenance-free | +++ | + | For many different branches of industry | ||

| Weight advantage | +++ | + | Aluminium approx. 2.7 g/cm³ Polymer approx.1.5 g/cm³ | Steel approx. 7.8 g/cm³ | Handling, automation, laboratory, leisure time |

| Highly dynamic responsiveness in the case of low loads | +++ | + | Packaging, handling, automation | ||

| Highly dynamic responsiveness in the case of high loads | + | +++ | Packaging, handling, automation | ||

| Stroke length variance | +++ | ++ | Camera technology, textile | ||

| Coefficient of friction | + | +++ | 0,15 - 0,3 µ | 0,001 - 0,05 µ | Manual adjustment, pivoting |

| Sensitivity to dirt | +++ | + | Packaging, stone, textile, paper, painting equipment | ||

| Noise dampening ¹ | +++ | ++ | 45-60 dB | 60-70 dB | Medicine, laboratory, furniture |

| Cost advantage | +++ | ++ | For many different branches of industry | ||

| Protection against corrosion | ++ | + | Filling systems, chemicals, food | ||

| Magnetism | + | +++ | Plastic, aluminium | Steel | Medicine, testing instruments |

| Chemical resistance | +++ | + | 1.4751 + iglide® T500 | 1.4112 | Medicine, food, electroplating, filling systems |

| Compatibility of the modules | +++ | + | Jig construction, assembly line automation | ||

| Quiet operation without any vibration | +++ | ++ | Camera technology, inspection, medicine, 3D printer | ||

| Short-stroke suitability | +++ | + | Textile, handling | ||

| Easy assembly and quick replacement | +++ | + | Jig construction, assembly line automation | ||

| Rigidity | + | +++ | Machine tools, CNC processing, electronics manufacturing | ||

| Long travels of more than 10 m | ++ | + | Camera, material handling, logistics | ||

| Temperature resistance | +++ | + | up to +250 °C | Chemicals | |

| Smooth running | + | +++ | Manual adjustment | ||

| Maximum acceleration ² | +++ | ++ | 50 m/s² | 15 m/s² | Automation, handling |

| Maximum speed ² | +++ | + | 30 m/s | 5 - 10 m/s | Automation, handling |

1) Measured in the igus® laboratory, 400 mm stroke, manual adjustment

2) When subjected to low loads, depending on installation size 0.1 to 5 kg

Characteristics: +++ strong ++ average + weak