Inquiry / Contact

igus® inc.

| General features | Unit | iglide® F | Test method |

| Density | g/cm³ | 1.25 | |

| Color | Black | ||

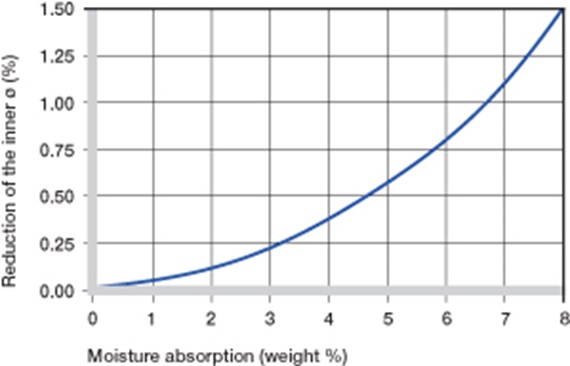

| Max. humidity absorption at 73° F/50% R. H. | Wt.-% | 1.8 | DIN 53495 |

| Max. water absorption | Wt.-% | 8.4 | |

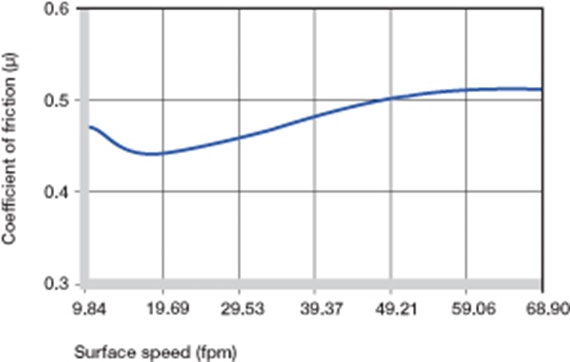

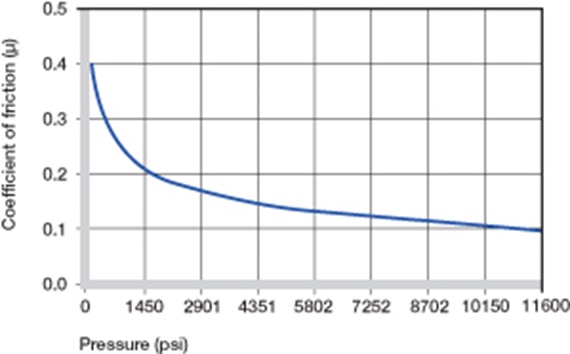

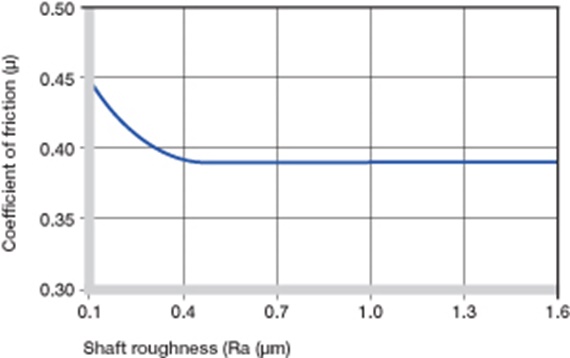

| Coefficient of surface friction, dynamic, against steel | µ | 0.1 - 0.39 | |

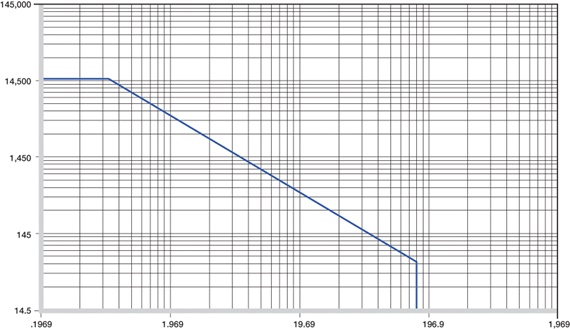

| p x v value, max. (dry) | psi x fpm | 9,700 | |

Mechanical properties | |||

| Modulus of elasticity | psi | 1,682,000 | DIN 53457 |

| Tensile strength at 68° F | psi | 37,710 | DIN 53452 |

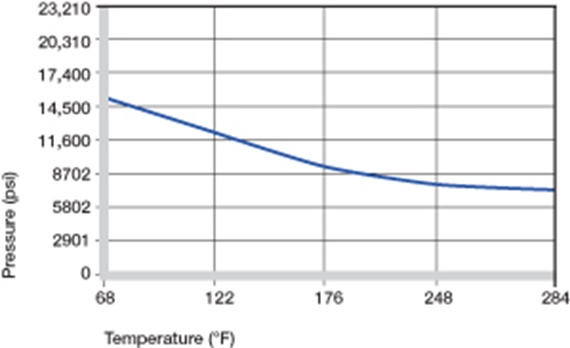

| Compressive strength | psi | 14,210 | |

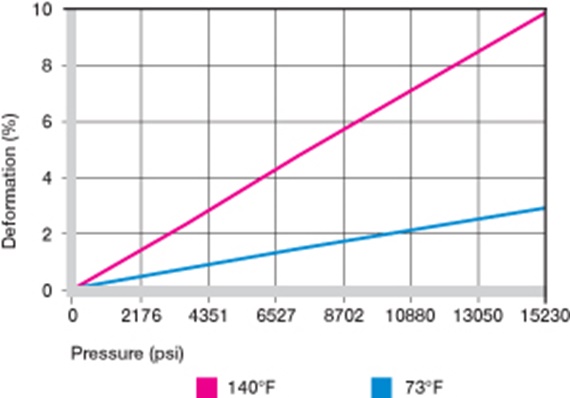

| Permissible static surface pressure (68° F) | psi | 15, 230 | |

| Shore D hardness | 84 | DIN 53505 | |

Physical and thermal properties | |||

| Upper long-term application temperature | °F | 284 | |

| Upper short-term application temperature | °F | 356 | |

| Lower application temperature | °F | -40 | |

| Heat conductivity | [W/m x K] | 0.65 | ASTM C 177 |

| Coefficient of thermal expansion (at 73°F) | [K-1 x 10-5 ] | 12 | DIN 53752 |

Electrical properties | |||

| Specific forward resistance | Ωcm | < 10 3 | DIN IEC 93 |

| Surface resistance | Ω | < 10 2 | DIN 53482 |

| fpm | Rotating | Oscillating | Linear |

| Continuous | 157 | 118 | 590 |

| Short-term | 295 | 216 | 1181 |

| iglide® F | Application temperature |

| Lower | - 40 °F |

| Upper, long-term | + 284 °F |

| Upper, short-term | + 356 °F |

| Additional axial securing | + 221 °F |

| iglide® F | Dry | Grease | Oil | Water |

| Coefficients of friction µ | 0.08 - 0.15 | 0.09 | 0.04 | 0.04 |

| Diameter d1 [inch] |

Shaft h9 [inch] |

iglide® F D11 [inch] |

| Up to 0.019685 | 0 - 0.0009843 | 0.0007874 - 0.0031496 |

| > 0.1181 to 0.2362 | 0 - 0.0011811 | 0.0011811 - 0.0041339 |

| > 0.2362 to 0.3937 | 0 - 0.0014173 | 0.0015748 - 0.0051181 |

| > 0.3937 to 0.7087 | 0 - 0.0016929 | 0.0019685 - 0.0062992 |

| > 0.7087 to 1.1811 | 0 - 0.0020472 | 0.0025591 - 0.0076771 |

| > 1.1811 to 1.9685 | 0 - 0.0024409 | 0.0031496 - 0.0094488 |

| Medium | Resistance |

| Alcohol | + to 0 |

| Hydrocarbons, chlorinated | + |

| Greases, oils, without additives | + |

| Fuels | + |

| Weak acids | 0 to - |

| Strong acids | - |

| Weak alkaline | + |

| Strong alkaline | + to 0 |

| Specific forward resistance | < 103 Ωcm |

| Surface resistance | < 102 Ω |