Inquiry / Contact

igus® inc.

| General features | Unit | iglide® H370 | Test method |

| Density | g/cm³ | 1.66 | |

| Color | Gray | ||

| Max. moisture absorption at 73° F/50% R. H. | Wt.-% | < 0.1 | DIN 53495 |

| Max. moisture absorption | Wt.-% | < 0.1 | |

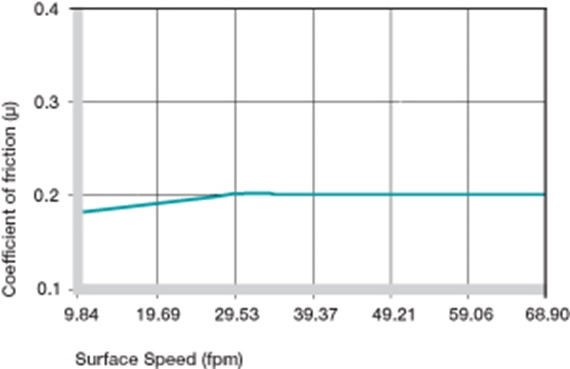

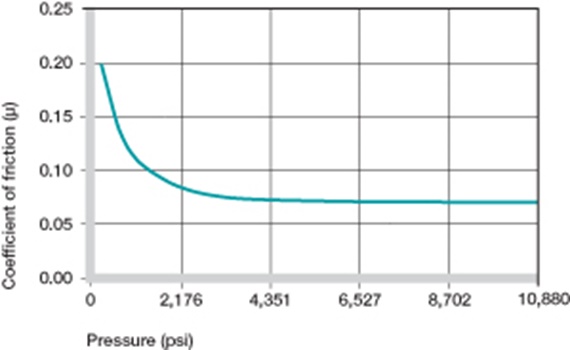

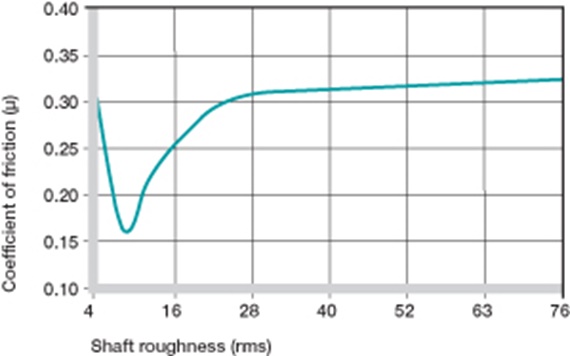

| Coefficient of surface friction, dynamic, against steel | µ | 0.07 - 0.17 | |

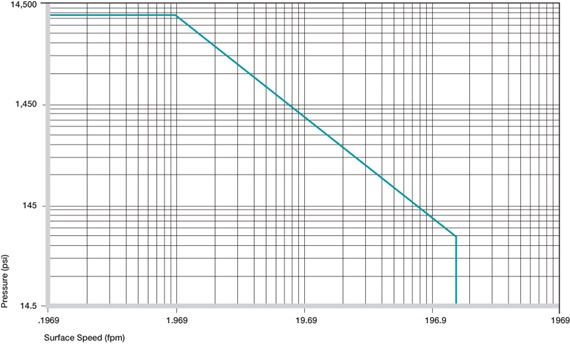

| p x v value, max. (dry) | psi x fpm | 21,100 | |

Mechanical properties | |||

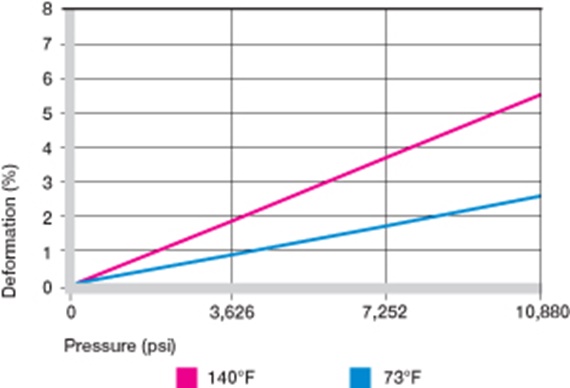

| Modulus of elasticity | psi | 1,610,000 | DIN 53457 |

| Tensile strength at 68° F | psi | 19,580 | DIN 53452 |

| Compressive strength | psi | 11,460 | |

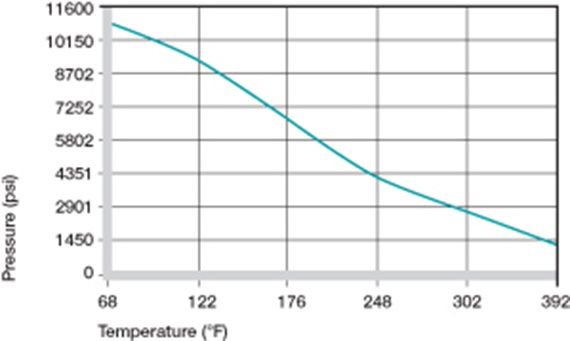

| Permissible static surface pressure (68° F) | psi | 10,880 | |

| Shore D hardness | 82 | DIN 53505 | |

Physical and thermal properties | |||

| Max. long-term application temperature | °F | 392 | |

| Max. short-term application temperature | °F | 464 | |

| Min. application temperature | °F | -40 | |

| Thermal conductivity | W/m x K | 0,5 | ASTM C 177 |

| Coefficient of thermal expansion | K-1 x 10-5 | 5 | DIN 53752 |

Electrical properties | |||

| Specific volume resistance | Ωcm | < 10 5 | DIN IEC 93 |

| Surface resistance | Ω | < 10 5 | DIN 53482 |

| fpm | Rotating | Oscillating | Linear |

| Constant | 236 | 157 | 787 |

| Short-term | 295 | 216 | 984 |

| iglide® H370 | Application temperature |

| Lower | - 40 °F |

| Upper, long-term | + 392 °F |

| Upper, short-term | + 464 °F |

| Additional axial securing | + 212 °F |

| iglide® H370 | Dry | Grease | Oil | Water |

| Coefficients of friction µ | 0,07 - 0,17 | 0,09 | 0,04 | 0,04 |

| Diameter d1 [mm] | Shaft h9 [mm] | iglide® H F10 [mm] |

| Up to 0.019685 | 0 - 0.0009842 | +0.0002362 + 0.0018110 |

| > 0.118 to 0.236 | 0 - 0.0011811 | +0.0003937 + 0.0022835 |

| > 0.236 to 0.394 | 0 - 0.0014173 | +0.0005118 + 0.0027953 |

| > 0.394 to 0.709 | 0 - 0.0016929 | +0.0006299 + 0.0033858 |

| > 0.709 to 1.181 | 0 - 0.0020472 | +0.0007874 + 0.0040945 |

| > 1.181 to 1.969 | 0 - 0.0024409 | +0.0009843 + 0.0049213 |

| > 1.969 to 3.150 | 0 - 0.0029134 | +0.0011811 + 0.0059055 |

| Medium | Resistance |

| Alcohol | + |

| Hydrocarbons, chlorinated | + |

| Greases, oils, without additives | + |

| Fuels | + |

| Weak acids | + to 0 |

| Strong acids | + to - |

| Weak alkaline | + |

| Strong alkaline | + |

| Specific volume resistance | < 105 Ωcm |

| Surface resistance | < 105 Ω |