Inquiry / Contact

igus® inc.

| General features | Unit | iglide® H4 | Test method |

| Density | g/cm³ | 1,79 | |

| Color | Brown | ||

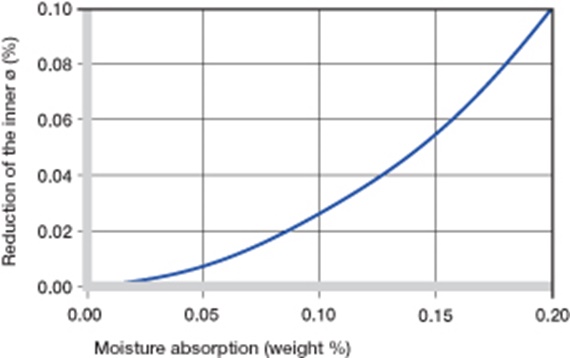

| Max. moisture absorption at 73° F/50% R. H. | Wt.-% | 0,1 | DIN 53495 |

| Max. moisture absorption | Wt.-% | 0,2 | |

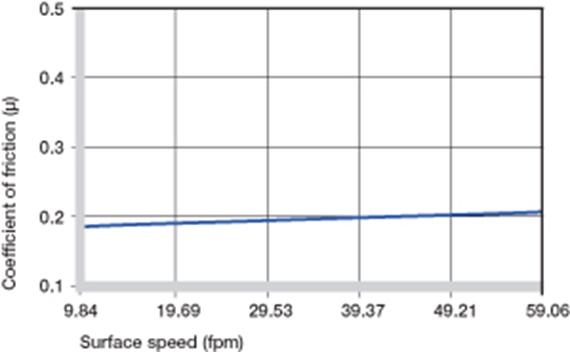

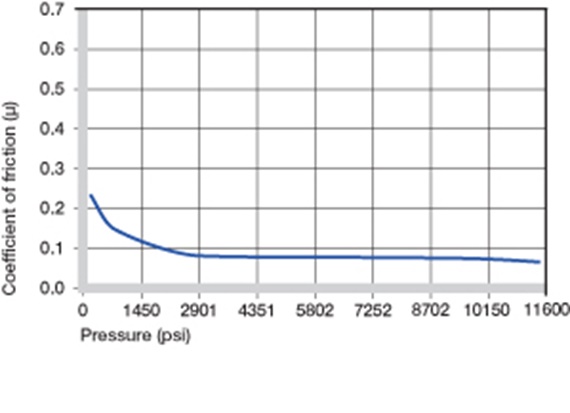

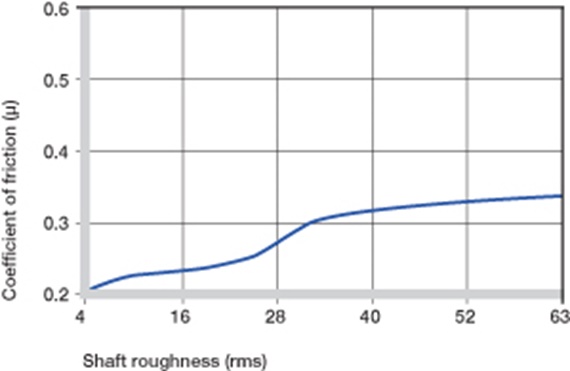

| Coefficient of friction, dynamic against steel | µ | 0.08 - 0.25 | |

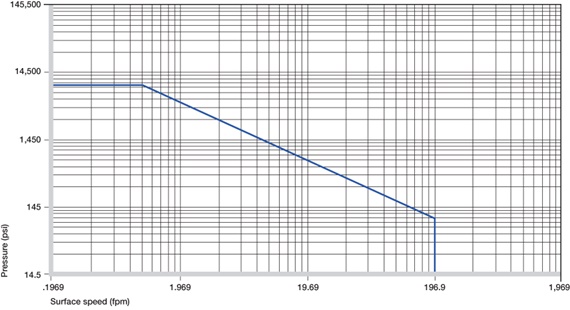

| p x v value, max. (dry) | psi x fpm | 19,500 | |

Mechanical properties | |||

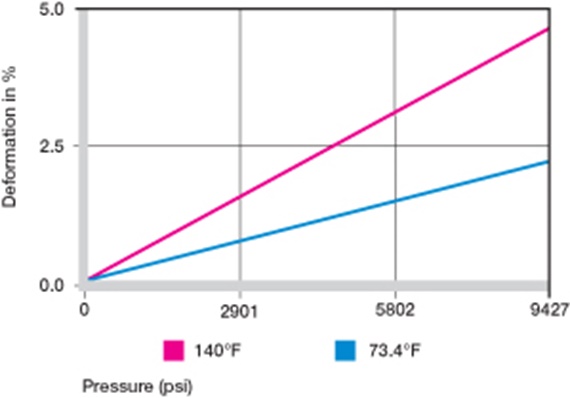

| Modulus of elasticity | psi | 1,088,000 | DIN 53457 |

| Tensile strength at 68° F | psi | 17,400 | DIN 53452 |

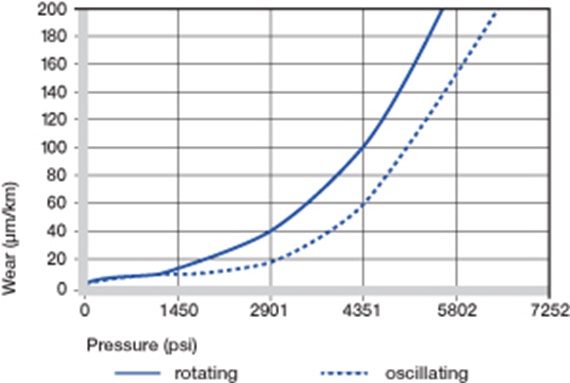

| Compressive strength | psi | 7,252 | |

| Permissible static surface pressure (68° F) | psi | 9,427 | |

| Shore D hardness | 80 | DIN 53505 | |

Physical and thermal properties | |||

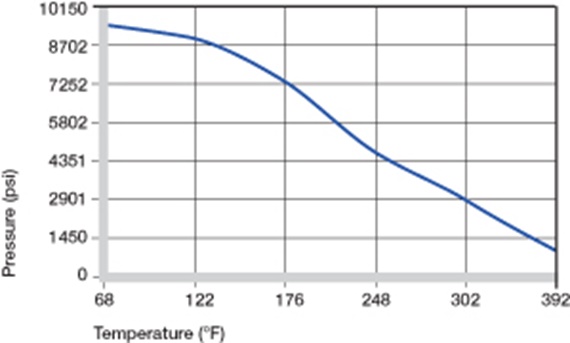

| Upper long-term application temperature | °F | 392 | |

| Upper short-term application temperature | °F | 464 | |

| Lower application temperature | °F | -40 | |

| Thermal conductivity | W/m x K | 0.24 | ASTM C 177 |

| Coefficient of thermal expansion (at 73° F) | K-1 x 10-5 | 5 | DIN 53752 |

Electrical properties | |||

| Specific volume resistance | Ωcm | > 1013 | DIN IEC 93 |

| Surface resistance | Ω | > 1012 | DIN 53482 |

| fpm | Rotating | Oscillating | Linear |

| Continuous | 197 | 138 | 197 |

| Short-term | 295 | 216 | 393 |

| iglide® H4 | Application temperature |

| Lower | - 40 °F |

| Upper, long-term | + 392 °F |

| Upper, short-term | + 464 °F |

| Additional axial securing | + 230 °F |

| iglide® H4 | Dry | Grease | Oil | Water |

| Coefficients of friction µ | 0.08 - 0.25 | 0.09 | 0.04 | 0.04 |

| Diameter d1 [mm] | Shaft h9 [mm] | iglide® H4 F10 [mm] |

| Up to 0.5 | 0 - 0,025 | +0,006 + 0,046 |

| > 3 to 6 | 0 - 0,030 | +0,010 + 0,058 |

| > 6 to 10 | 0 - 0,036 | +0,013 + 0,071 |

| > 10 to 18 | 0 - 0,043 | +0,016 + 0,086 |

| > 18 to 30 | 0 - 0,052 | +0,020 + 0,104 |

| > 30 to 50 | 0 - 0,062 | +0,030 + 0,150 |

| Medium | Resistance |

| Alcohol | + |

| Hydrocarbons, chlorinated | + |

| Greases, oils, without additives | + |

| Fuels | + |

| Weak acids | + to 0 |

| Strong acids | + to - |

| Weak alkaline | + |

| Strong alkaline | + |

| Specific forward resistance | > 1013 Ωcm |

| Surface resistance | > 1012 Ω |