Inquiry / Contact

igus® inc.

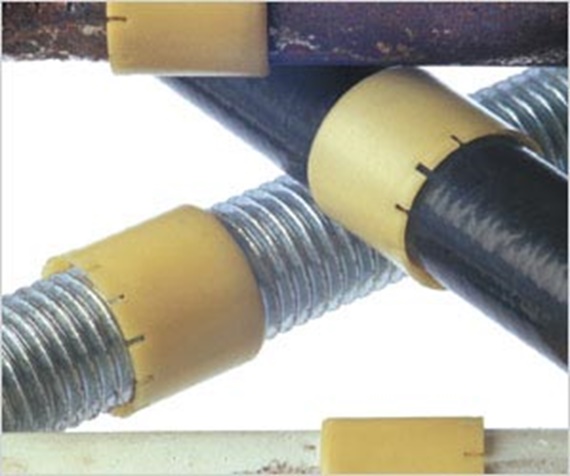

Cost-effective plastic plain bearing system

Independent of shaft material

Independent of shaft surface

Protects expensive and sensitive shafts

Extraordinary wear resistance with light and slow movements.

Constantly low coefficients of friction

Simple installation

Absolute corrosion resistance

Delivered off the shelf

d1 [inch]: |

|

d2 [inch]: |

|

| Part no. | d1 | d2 | b1 | ||

|---|---|---|---|---|---|

| PEPSM-0610-10 | 0.24 | 0.39 | 0.39 | Upon request | |

| PEPSM-0812-12 | 0.31 | 0.47 | 0.47 | Upon request | |

| PEPSM-1014-12 | 0.39 | 0.55 | 0.47 | 3.67 USD | |

| PEPSM-1216-15 | 0.47 | 0.63 | 0.59 | Upon request | |

| PEPSM-1620-20 | 0.63 | 0.79 | 0.79 | 10.87 USD | |

| PEPSM-2023-20 | 0.79 | 0.91 | 0.79 | 9.84 USD |

d1 [inch]: |

|

d2 [inch]: |

|

| Part no. | d1 | d2 | b1 | ||

|---|---|---|---|---|---|

| PEPSI-0406-06 | 1/4 | 3/8 | 3/8 | Upon request | |

| PEPSI-0608-08 | 3/8 | 1/2 | 1/2 | Upon request | |

| PEPSI-0810-08 | 1/2 | 5/8 | 1/2 | Upon request | |

| PEPSI-1012-12 | 5/8 | 3/4 | 3/4 | Upon request | |

| PEPSI-1214-12 | 3/4 | 7/8 | 3/4 | Upon request | |

| PEPSI-1618-16 | 1 | 1 1/8 | 1 | Upon request |