Inquiry / Contact

igus® inc.

| General features | Unit | iglide® UW500 | Test method | |

| Density | g/cm³ | 1.49 | ||

| Color | Black | |||

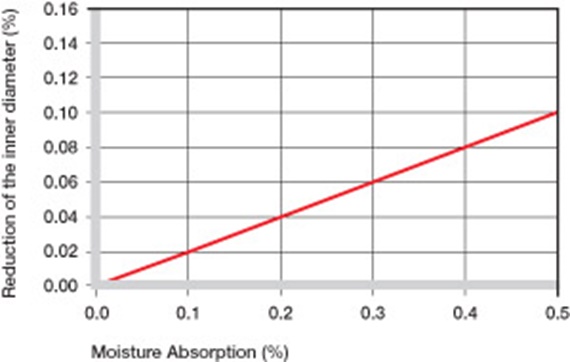

| Max. humidity absorption at 73° F/50% R. H. | Wt.-% | 0,1 | DIN 53495 | |

| Max. water absorption | Wt.-% | 0.5 | ||

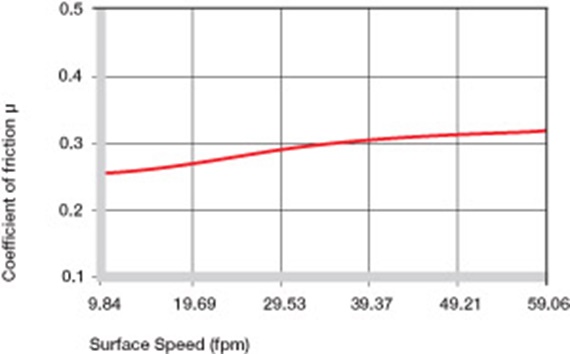

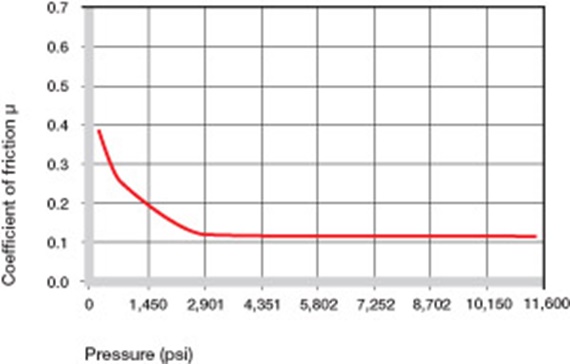

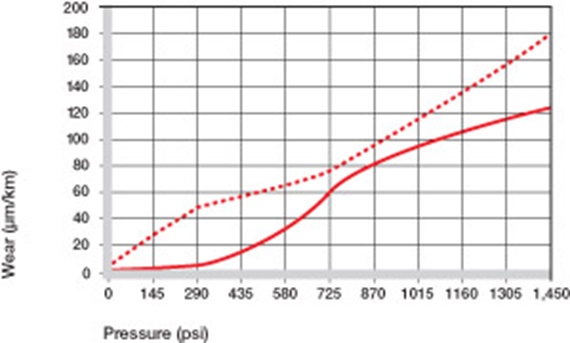

| Coefficient of friction, dynamic against steel | µ | 0.20 - 0.36 | ||

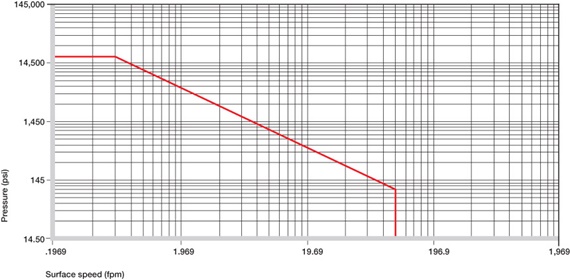

| p x v value, max. (dry) | psi x fpm | 10,000 | ||

Mechanical properties |

||||

| Modulus of elasticity | psi | 2,321.000 | DIN 53457 | |

| Tensile strength at 68° C | psi | 37,710 | DIN 53452 | |

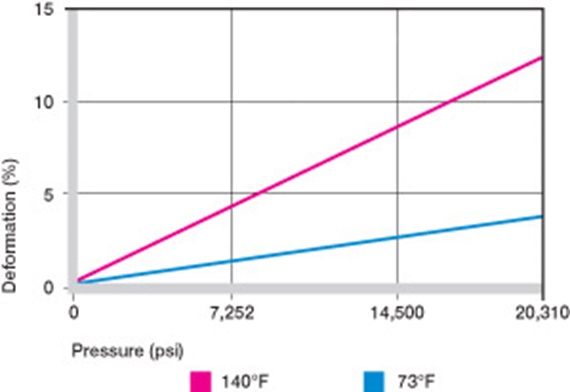

| Compressive strength | psi | 20,310 | DIN 53452 | |

| Maximum recommended surface pressure (68° F) | psi | 20,310 | ||

| Shore D hardness | 86 | DIN 53505 | ||

Physical and thermal properties | ||||

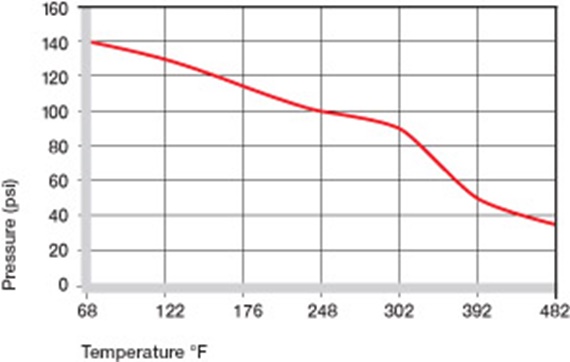

| Upper long-term application temperature | °F | 482 | ||

| Upper short-term application temperature | °F | 572 | ||

| Lower application temperature | °F | 599 | ||

| Thermal conductivity | [W/m x K] | 0.60 | ASTM C 177 | |

| Coefficient of thermal expansion (at 73° F) | [K-1 x 10-5 ] | 4 | DIN 53752 | |

Electrical properties | ||||

| Specific volume resistance | Ωcm | < 10 9 | DIN IEC 93 | |

| Surface resistance2) | Ω | < 10 9 | DIN 53482 | |

| fpm | Rotating | Oscillating | Linear |

| Constant | 158 | 118 | 394 |

| Short-term | 295 | 217 | 591 |

| iglide® UW500 | Application temperature |

| Lower | - 148 °F |

| Upper, long-term | + 482 °F |

| Upper, short-term | + 572 °F |

| Additional axial securing | + 302 °F |

| iglide® UW500 | Dry | Grease | Oil | Water |

| Coefficients of friction µ | 0.1 - 0.4 | 0.09 | 0.04 | 0.04 |

| Diameter d1 [mm] | Shaft h9 [mm] | iglide® UW500 F10 [mm] |

| Up to 0.5 | 0 - 0,025 | +0,006 + 0,046 |

| > 3 to 6 | 0 - 0,030 | +0,010 + 0,058 |

| > 6 to 10 | 0 - 0,036 | +0,013 + 0,071 |

| > 10 to 18 | 0 - 0,043 | +0,016 + 0,086 |

| > 18 to 30 | 0 - 0,052 | +0,020 + 0,104 |

| > 30 to 50 | 0 - 0,062 | +0,030 + 0,150 |

| Medium | Resistance |

| Alcohol | + |

| Hydrocarbons, chlorinated | + |

| Greases, oils, without additives | + |

| Fuels | + |

| Weak acids | + |

| Strong acids | + |

| Weak alkaline | + |

| Strong alkaline | + |

| Specific volume resistance | > 109 Ωcm |

| Surface resistance | > 109 Ω |