Inquiry / Contact

igus® inc.

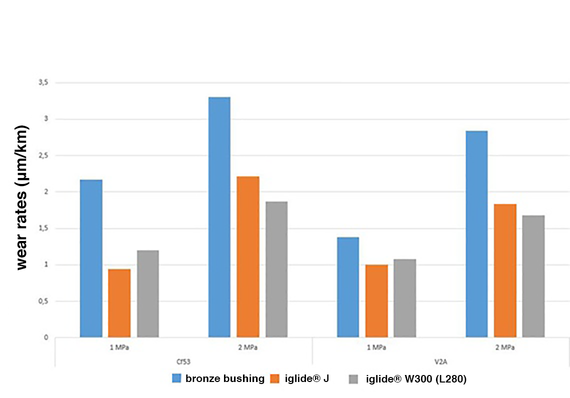

| Load: | 1 & 2 MPa |

| Speed: | 0,01 m/s |

| Shaft: | Cf53 and V2A |

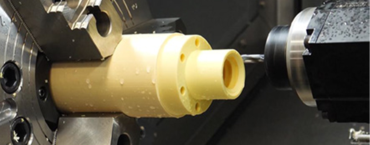

| Plain bearing materials: | iglide® J and iglide® L280 |

Whether you're interested in turnkey, fully assembled solutions or looking to build your own customizable project, learn more about how igus® can assist you with a solution based on your specific application and requirements. Contact us via the form below or call us at (800) 521-2747 to discuss your project today!