Plastic Bearings in Packaging Machine

A packaging machine that can produce up to 210 packages per minute uses iglide® plastic bushings from igus® to help guarantee quick timing and positional accuracy.

Design criteria: Lightweight and space-saving

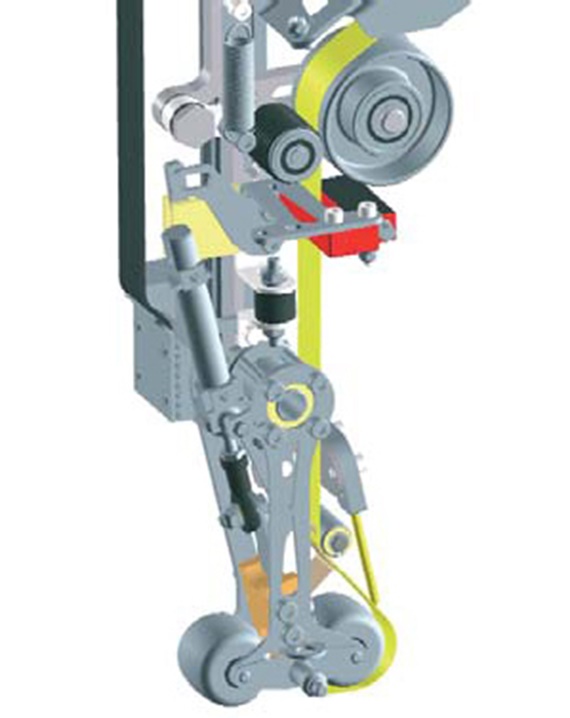

A manufacturer providing various types of packages with a carrier handle uses a highly dynamic application head that has to be as lightweight and small as possible. The application head starts spontaneously on demand through a simple pressure-sensor system and provides up to 70 packages with a carrier handle in one minute.The operation takes place in single-, dual- or three-track options - which means up to 210 packages are possible per minute.

To guarantee this quick timing and positional accuracy, the bearings used in the application head had to be lightweight and space saving.

iglide® plastic bushings and igubal® rod end bearings fulfilled not only these criteria, but helped to reduce manufacturing costs, lower the coefficient of friction, and enhance service life. They are lubrication- and maintenance-free, as well as vibration dampening.

The packaging machine uses iglide® G300 plastic bushings, which are economical all-rounders that can withstand high loads and chemicals. The self-lubricating effect means they are both maintenance-free and dry-running, as well as insensitive to dust and dirt. Coefficients of friction and wear rate are kept as low as possible.

Said a spokesperson:

“For us, there was no alternative to igus®; taking into consideration the permissible weight, space and cost requirements. The decision to use igus® as our supplier made thing much easier for us. We had already worked with them many times before and the team there is always innovative and excellent at overseeing projects."

“For us, there was no alternative to igus®; taking into consideration the permissible weight, space and cost requirements. The decision to use igus® as our supplier made thing much easier for us. We had already worked with them many times before and the team there is always innovative and excellent at overseeing projects."