Robotics News 2022

TRX | from design study to test product

triflex® R retraction system in size 50

triflex® R fibre-rod in size 30

Dresspacks for Low Cost Automation

The energy supply systems for the robolink® DP and ReBeL fromigus® are now available on the RBTX platform as a complete

kit or can be configured with just a click in the robot equipment configurator.Online configurator

Low Cost Automation Homepage

Arguments for a Low Cost Automation dresspack

Tech up

- Lightweight

- For safe guidance of cables and hoses on the robot

- Space-saving

- Can be adapted to any application

Cost down

- Save assembly time: simple, fast and tool-free assembly (ReBeL®)

- Components individually interchangeable

Sustainability

- No lubricants necessary

- Parts are reusable

- igus® has been an investor in Mura

Technology from the very beginning and is advancing chemical recycling. From plastic waste to crude oil in 20 minutes:

igus.eu/hydroprs - Have your energy chain recycled at the end of its life cycle with the igus® chainge recycling program. No matter from which

manufacturer: www.igus.eu/chainge

Retraction system (RS) for industrial robots in size 50

- Closes the gap between sizes 40 and 60

- Particularly suitable for applications with a high level of dirt

- The energy chain is available as an enclosed tube (TRC) or a variant that can be filled externally (TRE)

Go to shop

Arguments for the use of a retraction system

Tech up

- Modular design

- Dirt-resistant / tough

- Retraction distance up to 460mm

- Compatible with all existing triflex® R adapters

- With cover (optional)

- Available as a enclosed (TRC) or easy (TRE) design

Cost down

- Low purchase price

- Low maintenance

- Quick assembly

- Cost-effective in case of repair (quick and easy replacement of individual components is possible)

Proof

- A system solution proven and tested in thousands of applications

- Example of an application of an RS system in welding technology

- Example application of an RS system in body shop

Sustainability

- No lubricants necessary

- Parts are reusable

- Have your energy chain recycled at the end of its life cycle with the igus® chainge recycling program. No matter from which

manufacturer: www.igus.eu/chainge

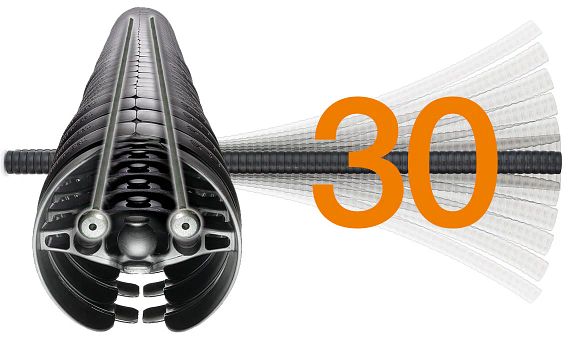

Fibre-rod in size 30

- Now also for the smallest triflex R chain size

- Ideal for applications with cobots

- Directional pretension from 300mm to 800mm

Go to shop

Arguments for the use of a fibre-rod

Tech up

- Directed pretension

- Module length up to 800mm

- Lightweight, therefore ideal for robots with low

payloads - Contactless energy supply possible on the robot, therefore low wear

Cost down

- Low purchase price

- Low maintenance

- Quick assembly

- Cost-effective in case of repair (quick and easy replacement of individual components is possible)

Proof

- A system solution proven and tested in thousands of applications

- Example of an application of a fibre-rod in the automotive industry

- Example of an application of a fibre-rod in the field of milling

Sustainability

- No lubricants necessary

- Parts are reusable

- Have your energy chain recycled at the end of its life cycle with the igus® chainge recycling program. No matter from which

manufacturer: www.igus.eu/chainge