Inquiry / Contact

igus® inc.

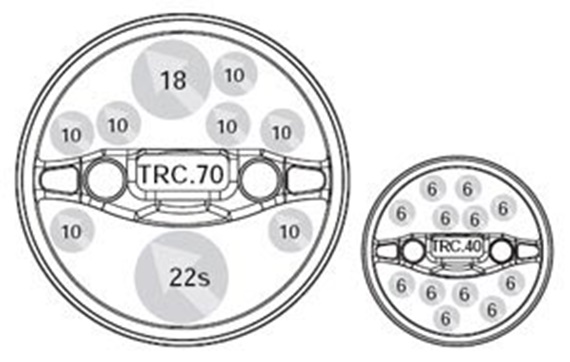

| For series: | Useable surfaces |

|---|---|

| inch² (mm²) | |

| TRC.30 | .48 (313) |

| TRC.40 | .78 (508) |

| TRC.60 | 1.77 (1,144.6) |

| TRC.70 | 2.77 (1,788) |

| TRC.85 | 3.77 (2,431) |

| TRC.100 | 4.92 (3,177) |

Example for determining the cable area:

| ACable | = | d² x π 4 |

| Examples: | ||

| A1 | = | (10 mm x 10 mm x π) / 4 |

| = | 78.5 mm² x 7 (No. of conduits) | |

| = | 549.50 mm² | |

| A2 | = | (18 mm x 18 mm x π) / 4 |

| = | 254.34 mm² | |

| A3 | = | (22 mm x 22 mm x π) / 4 |

| = | 379.94 mm² | |

| ACable | = | A1 + A2 + A3 = 1,183.7 mm² |

Monday to Friday from 8 am - 8 pm

24h