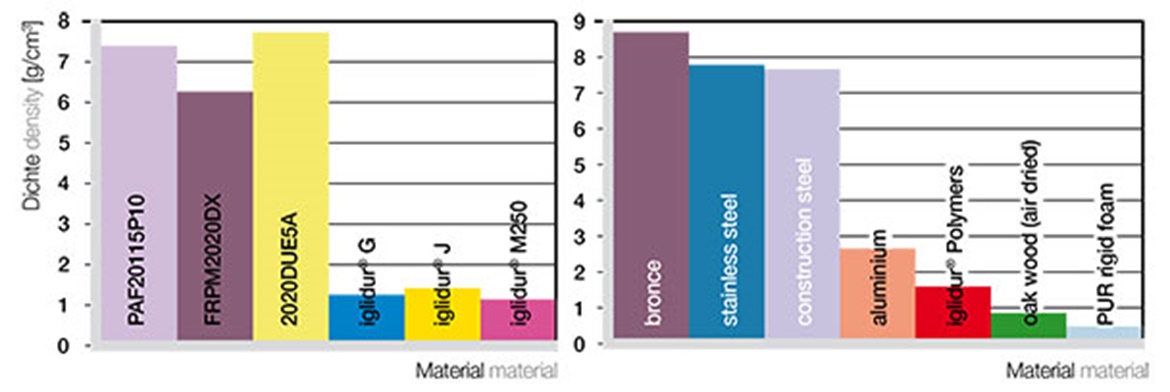

Lower weight, less installation space and reduced costs

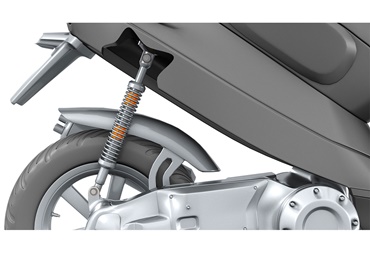

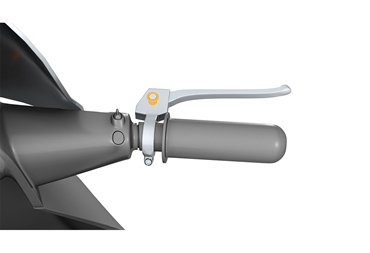

Dry running, no external lubrication/maintenance necessary

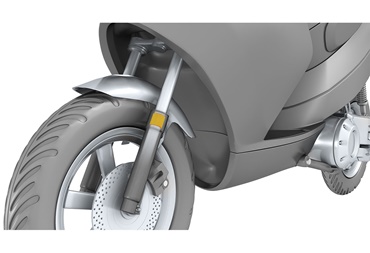

Minimized degree of noise and vibration

Reduced friction and longer service life

Lowest humidity absorption

Extremely wear-resistant, especially at pivoting loads up to 2,901 psi

Versatile: good with many different shaft materials

Good with edge loads

Low wear with numerous shaft materials

Low coefficients of friction while running dry

Vibration-damping

Good chemical resistance

Best performance with soft shafts

Lowest humidity absorption

Usable underwater

Low-cost

Chemical resistant

For high temperatures/p>

Low-cost

More wear-resistant than PTFE-bonds

Higher load capacity

Defined dimensions

Different materials, e.g. iglide® J, J350…

Low wear with numerous shaft materials

Low coefficients of friction while running dry

Vibration-damping

Good chemical resistance

Best performance with soft shafts

Lowest humidity absorption

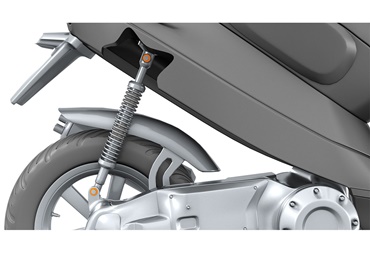

Maintenance-free, dry operation

High wear-resistance

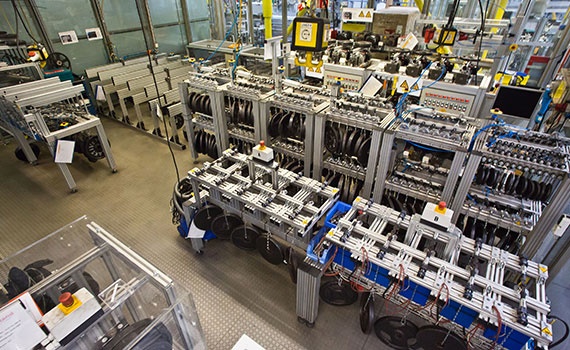

Insensitive to dirt and dust

Over 650 dimensions available from stock

Low-cost

Lowest humidity absorption

Extremely wear-resistant, especially at pivoting loads up to 2,901 psi

Versatile: good with many different shaft materials

Good with edge loads

Very low coefficient of friction on steel

For continuous use up to +356°F

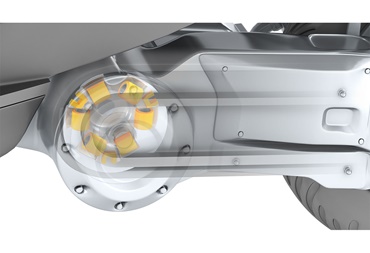

Particularly well suited for rotations

Maintenance-free, dry operation

Insensitive to dirt and dust

Over 650 dimensions available from stock

Low-cost

Simple installation, maintenance-free

Insensitivity to dirt through dry operation.

Low weight and low-noise operation

Square rail with floating bearing function for installation in a corner

Manually adjustable bearing clearance (optional)

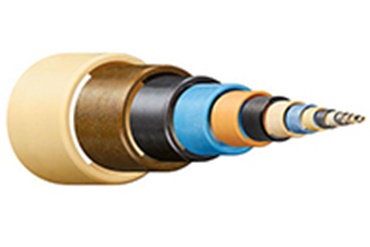

Base polymer

Fibers and filling material

Solid lubricants