Inquiry / Contact

igus® inc.

| General features | Unit | iglide® A500 | Test method |

| Density | g/cm³ | 1.28 | |

| Color | Brown | ||

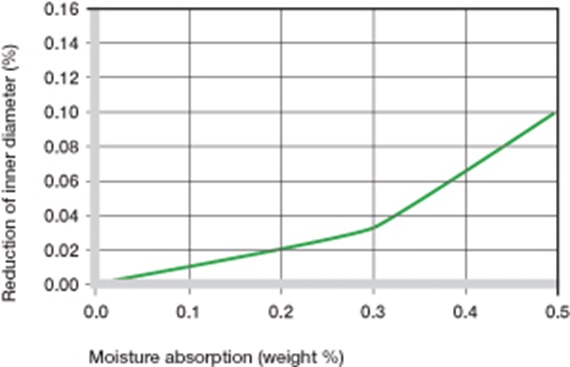

| Max. humidity absorption at 73° F/50% R. H. | Wt.-% | 0.3 | DIN 53495 |

| Max. water absorption | Wt.-% | 0.5 | |

Mechanical properties | |||

| Bending E-module | psi | 522,000 | DIN 53457 |

| Bending strength at 68° F | psi | 20,300 | DIN 53452 |

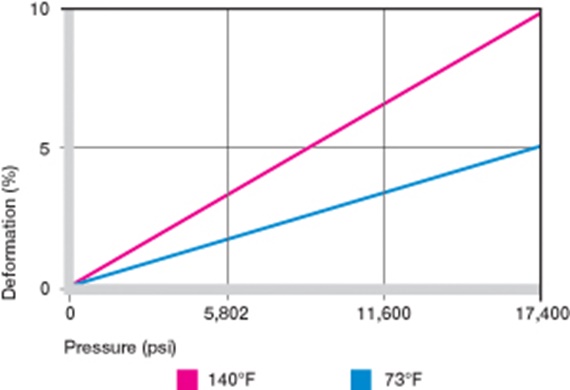

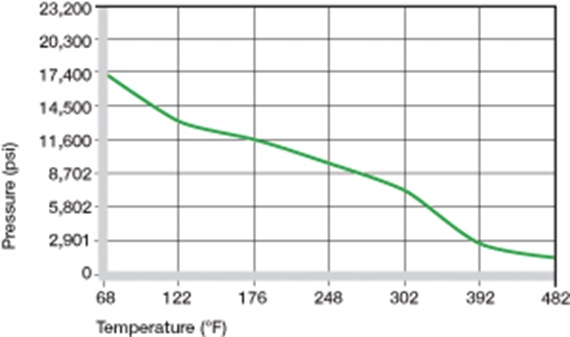

| Maximum recommended surface pressure (68° F) | psi | 17,400 | |

| Shore D hardness | 83 | DIN 53505 | |

Physical and thermal properties | |||

| Upper long-term application temperature | °F | 482 | |

| Upper short-term application temperature | °F | 572 | |

| Lower application temperature | °F | -148 | |

Electrical properties | |||

| Specific forward resistance | Ωcm | > 1014 | DIN IEC 93 |

| Surface resistance | Ω | > 1013 | DIN 53482 |

| ftpm | Rotating | Oscillating | Linear |

| Continuous | 118 | 78 | 196 |

| Short-term | 196 | 137 | 393 |

| iglide® A500 | Application temperature |

| Lower | -148 °F |

| Upper, long-term | + 482 °F |

| Upper, short-term | + 572 °F |

| Additional axial securing | + 266°F |

| iglide® A500 | Dry | Grease | Oil | Water |

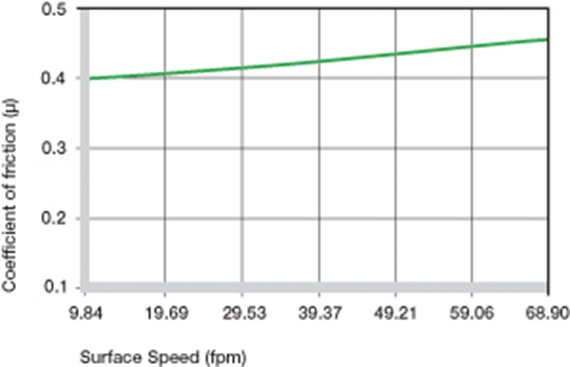

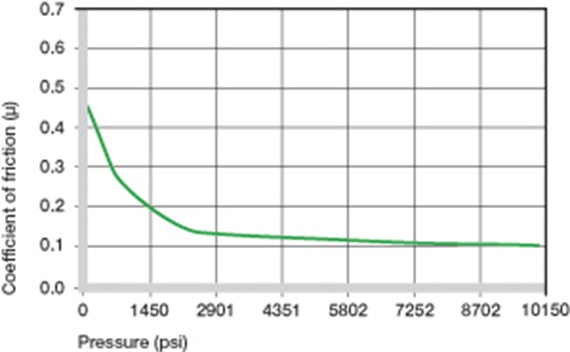

| Coefficients of friction | 0.10 - 0.40 | 0.09 | 0.04 | 0.04 |

| Diameter d1 [inch] |

Shaft h9 [inch] |

iglide® A290 F10 [inch] |

| Up to 0.019685 | 0 - 0.00098425 | +0.0002362 + 0.0018110 |

| > 0.1181 to 0.2362 | 0 - 0.0011811 | +0.0003937 + 0.0022835 |

| > 0.2362 to 0.3937 | 0 - 0.00141732 | +0.0005118 + 0.0027953 |

| > 0.3937 to 0.7087 | 0 - 0.00169291 | +0.0006299 + 0.0033858 |

| > 0.7087 to 1.1811 | 0 - 0.00204724 | +0.0007874 + 0.0040945 |

| > 1.1811 to 1.9685 | 0 - 0.00244094 | +0.0011811 + 0.0059055 |

| Medium | Resistance |

| Alcohol | + |

| Hydrocarbons, chlorinated | + |

| Greases, oils, without additives | + |

| Fuels | + |

| Weak acids | + |

| Strong acids | + |

| Weak alkaline | + |

| Strong alkaline | + |

| Specific volume resistance | > 1014 Ωcm |

| Surface resistance | > 1013 Ω |