Change Language :

Dry-running & maintenance-free iglide plain bearings

Wherever metal moves on metal, regular lubrication is necessary. The expenses incurred for lubricants, maintenance and labor cost millions. Anyone who has ever experienced the damage caused by inadequate lubrication knows that this is where it gets really expensive. igus offers you dry-running bearing technology with which you can save these costs.

How it works? iglide plain bearings contain solid lubricant particles, millions of which are embedded in small chambers in the material. This creates the so-called self-lubricating effect through which iglide plastic plain bearings

do not require any additional lubricants. A study by RWTH Aachen is the first to show the savings potential of self-lubricating plastic plain bearings in terms of costs for lubricants, personnel and maintenance.

What Our Customers Save

$3,12.12 USD costs 1

1,560 hours maintenance 2

180.08kg CO2equivalent 3

Heineken Brasil uses self-lubricating igus bearing technology in conveyor belts and thus increases reliability. Downtimes are thus reduced to a minimum.

$96.91 USD costs 1

13 hours maintenance 2

1.4kg CO2equivalent 3

Rockinger uses a self-lubricating wear insert in the KS80 ball coupling, which makes lubrication superfluous and minimizes maintenance.

$58.24 USD costs 1

13 hours maintenance 2

3.8kg CO2equivalent 3

By using one plastic bearing per labelling station, Krones AG saves over $50 and 13 hours of maintenance time per year.

$1,220.19 USD costs 1

73.3 hours maintenance 2

79.36kg CO2equivalent 3

The construction machinery manufacturer Wacker Neuson uses dirt-resistant and maintenance-free iglide plain bearings at 25 bearing points in compact excavator arm systems.

$97.62 USD costs 1

14.7 hours maintenance 2

6.3kg CO2equivalent 3

Lemken specializes in manufacturing agricultural equipment for soil cultivation, sowing and crop protection and saves 22 lubrication points per cultivator.

1 Annual cost savings due to using plastic plain bearings per machine/system

2 Annual time savings due to using of plastic plain bearings per machine/system

3 Annual savings of CO2 equivalents due to using plastic plain bearings per machine/system

How does self-lubrication work?

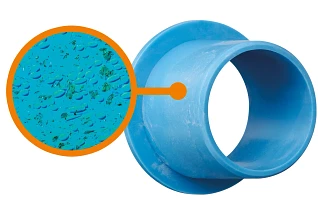

200-fold enlargement of base polymers with fibers and solid lubricants of an iglide plastic bearing

iglide plain bearings contain millions of solid lubricants in tiny chambers that are embedded in fiber-reinforced material. The material releases tiny amounts of solid lubricants from these chambers. This is enough to lubricate the immediate surroundings.

They also help reduce the coefficient of friction of the iglide materials. The integration in the tiny chambers also has the advantage that the solid lubricants cannot be squeezed to other places, as is the case with conventional lubrication.

Thanks to the self-lubricating effect, maintenance is minimized. Regular relubrication is not necessary due to the incorporated solid lubricants and dirt or dust cannot adhere to the bearing point.

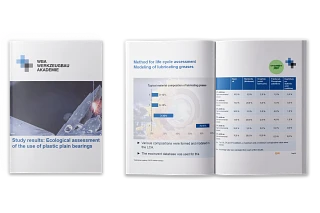

RWTH study: up to $15 million potential savings per year thanks to dry-running plastics

An independent study commissioned by igus quantifies the ecological and economic benefits of self-lubricating plastic plain bearings for the first time. It was carried out by the Werkzeugbau Akademie, a research company that works on the RWTH Aachen Campus as part of one of Europe's largest research laboratories in the field of production technology, together with the Fraunhofer Institute, among others.

As part of the study, expert interviews were conducted with nine companies from the automation technology, construction machinery, agricultural, food, packaging and bottling industries. The participants include B. CNH Industrial, Heineken and Krones AG.