Change Language :

iglide® A181 - technical data

Material data

| General Properties | Unit | iglide® A181 | Testing Method |

|---|---|---|---|

| Density | g/cm3 | 1.38 | |

| Color | blue | ||

| Max. moisture absorption at 73°F/50% r.h. | % weight | 0.2 | DIN 53495 |

| Max. moisture absorption | % weight | 1.3 | |

| Coefficient of surface friction, dynamic, against steel | µ | 0.10 - 0.21 | |

| p x v value, max. (dry) | psl x fpm | 8,750 |

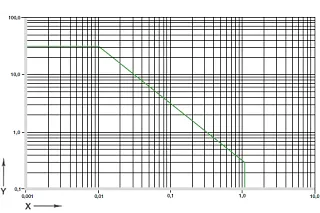

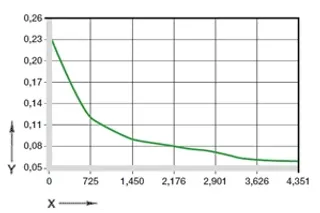

Fig. 01: Permissible p x v values for iglide® A181 running dry against a steel shaft, at 68°F

Bearings made from iglide® A181 are suitable for application in direct contact with food. This means they are the ideal solution for bearing applications on machines used by the food and packaging industry and medical equipment manufacturers, among others.

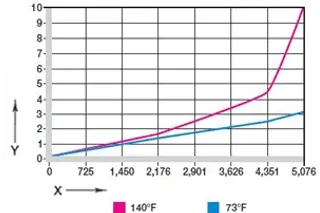

Figure 02: Deformation under load and temperatures

X = Pressure (psi)

Y = Deformatio [%]

Compressive Strength

With increasing temperatures, the compressive strength of iglide® A181 plain bearings decreases. The recommended maximum surface pressure is a mechanical material parameter. No conclusions regarding the tribological properties can be drawn from this. The graph at the right shows the elastic deformation of iglide® A181 during radial loading. At the recommended maximum surface pressure of 4,496 psi the deformation is less than 3%. Plastic deformation is minimal up to this radial load. However, it is also a result of the service time.

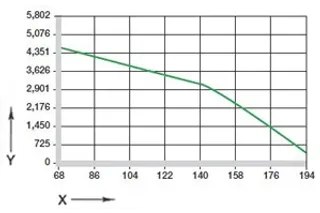

Figure 03: Recommended maximum static surface pressure if iglide® A181 as a result of the temperature (31 MPa to +68°F)

X = Temperature [°F]

Y = Pressure (psi)

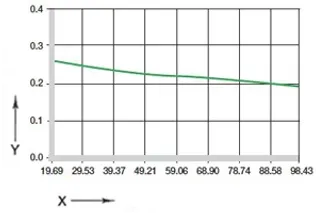

Figure 04: Coefficients of friction of iglide® A181 as a function ofthe running speed; p = 108 psi

X = Surface speed [fpm]

Y = Coefficient of friction [μ]

Friction and wear

Coefficient of friction and wear resistance alter with specific application parameters. For iglide® A181, the coefficient of friction μ isdependent on the surface speed of the shaft along with the shaft surface finish although generally speaking the effect is negligible asthe table below represents. The coefficient of friction increases quickly with any load under 725 psi. As the load increases the coefficientof friction reduces drastically. For iglide® A181, a ground surface with an average between 8-64 rms is recommended, givingthe user a wide range to work with.

Figure 05: Coefficients of friction of iglide® A181 as a function ofthe load, v = 1.97 fpm

X = Load [psi]

Y = Coefficient of friction [μ]

iglidur® A181

Dry

Grease

Oil

Water

Coefficients of Friction µ

0,05 - 0,23

0,09

0,04

0,04

Table 04: Coefficient of friction of iglide® A181 against steel (Shaft finish = 40 rms, 50 HRC)

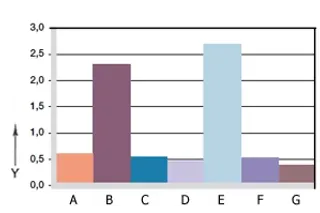

Figure 07: Wear of iglide® A181 with different shaft materials in rotational applications p = 145 psi, v = 59 fpm

Y = Wear [μm/km]

A = Hard-anodized aluminum

B = Automatic screw steel

C = 1050 Steel

D = 1050, hard chromed

E = HR Carbon Steel

F = 304 Stainless

G = 440B Steel

Shaft Materials

The graphs show the test results of iglide® A181 bearings runningagainst various shaft materials.Particular attention is paid in the food industry to corrosion-resistantshafts. The chart below shows that very low wear ratescan be achieved in combination with these shafts. As with many ofthe iglide® materials, wear rate increases with otherwise identicalparameters in rotation.