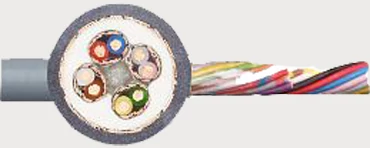

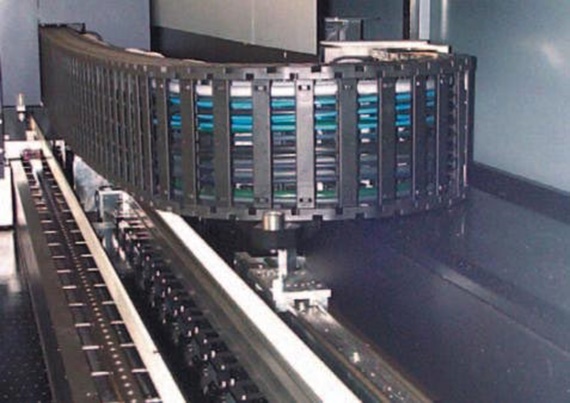

The term 'printing technology' refers to numerous methods of duplicating masters and templates. In the same way, igus® motion plastics® refer to numerous tribologically optimized plastic products, which helps you to reduce the cost of your equipment and increase its service life. Whether this is due to the absence of no external lubrication and maintenance or due to fail-safe cables and optimum cable guidance. From our range of 100,000 modular products, we always offer the right solution whatever the requirements are. Extremely low-vibration energy guides for very high acceleration rates, abrasion-resistant and confirmed to be in account with IPA DIN EN ISO Class 1, super-quiet from 32 dB(A), very high data rates CAT7, 600 MHz and a cable guarantee against failure for up to 4 years.