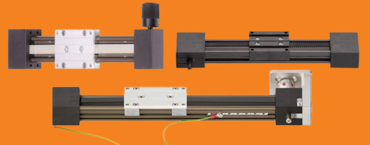

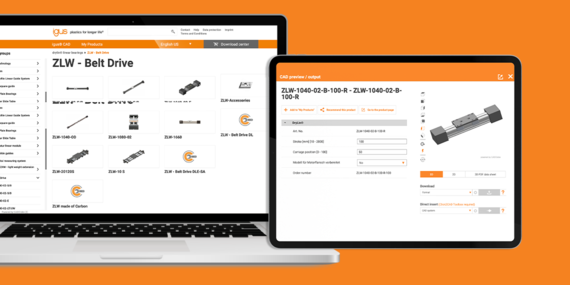

The drylin® ZLW is a line of toothed/timing-belt actuators that are best suited to move low loads at high speeds, even up to 5 m/s depending on the load. Each linear actuator system is designed with our own highly engineered,dry-running plastic bearing liners which enable quiet, grease-free and maintenance-free operation. Whether used as an individual system or as part of a gantry robot system, the ZLW series offers the ideal solution when both confined space and a high level of torque support are required. All drylin® ZLW belt driven linear actuators can be ordered ready for installation and configured with drylin® E stepper and DC motors.

A picking machine equipped with 2D and 3D cameras with drylin linear units with toothed belt drive (ZLW 1040 and ZLW 1080) ensures the automatic detection of empties. The systems are 100 percent self-lubricating and are characterized by extremely smooth running, high speeds and a high degree of accuracy.

The so-called "CocktailAvenue" is considered an innovation in the catering industry and provides automation behind the bar counter with mixed cocktails. In terms of technology, igus ensures a reliable operation of the construction with its product range. A drylin ZLW toothed belt axis works with an electric motor without the use of external lubricants and is completely vibration-free and insensitive to stubborn dirt. The timeless design of the linear axis also impresses.

Monday to Friday from 8 am - 8 pm

24h