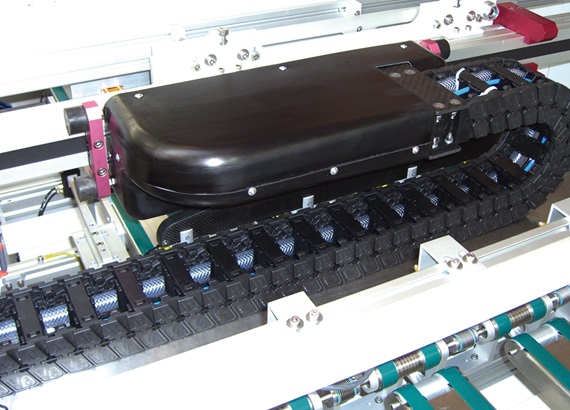

Fast wafer handling in the chip production industry.

Components for every cleanroom that improve technology and reduce costs

One igus® e-chain® of the E6 family accelerates the work sequences in the case of this application for wafer handling in the chip production industry. With the E6, the supply of energy at accelerations of up to 4 m/s2 and at speeds of up to 6 metres per second is not a problem. The minimum abrasion is also very important because a high degree of cleanliness is a decisive factor in the chip production industry. The E6 is cleanroom-suitable with IPA Fraunhofer certification.

Profile:

- Industry: cleanroom / semiconductor

- Application: Wafer handling

- Product: e-chain® - E6

- Requirements: The minimum abrasion is very important because a high degree of cleanliness is a decisive factor in the chip production industry.

Go to Cleanroom Overview

Selected products for the cleanroom industry

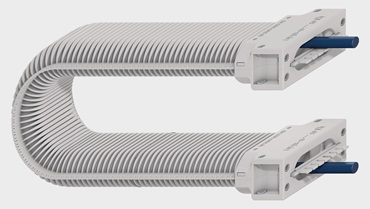

Flat cable guidance system

- Suitable for cleanroom IPA ISO Class 1

- Modular and compact design

- Cables can be replaced in minutes

- Optionally with co-ordinated CFCLEAN stranded structure for high dependability

e-skin flat

Two-piece corrugated tubes

- Suitable for cleanroom according to IPA ISO Class 1

- Two-piece, consisting of upper and lower shells

- Fast assembly due to "zipper" opening function

- For fast, short, unsupported applications

e-skin corrugated tubes

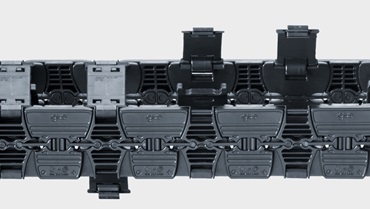

e-chain for high dynamics

- Cleanroom IPA ISO Class 1

- Very quiet: 32dB(A) at 1m/s

- Crossbars openable from both sides

- Smooth, cable-friendly interior

- Release pretension by turning the inner link

e-chain E6.1

Application examples for the cleanroom

Industry: Chip production/Semiconductor

Result: At as a 4-fold layer together with PVC & TPE cables from igus® ensures the reliable energy supply of an air bearing linear system.

e-skin flat in use in a linear system with air bearings

Solution: e-skin flat " - SKF12.4.03.01.1Result: At as a 4-fold layer together with PVC & TPE cables from igus® ensures the reliable energy supply of an air bearing linear system.

Learn more

Industry: Semiconductor manufacturing

Result: The patented zipper e-chain® system meets the required travel distance of about 290 mm, cycle numbers of 50-60 cycles per hour are achieved, usually in three-shift operation.

e-chain® systems in semiconductor manufacturing

Solution: zipper e-chain® in a hanging installation positionResult: The patented zipper e-chain® system meets the required travel distance of about 290 mm, cycle numbers of 50-60 cycles per hour are achieved, usually in three-shift operation.

Learn more

Industry: Chip production/Semiconductor

Result: With e-chain® - E6, the supply of energy for wafer handling in chip production involving acceleration rates of up to 4m/s2 and speeds of up to 6m/s is not a problem.

Wafer handling

Solution: e-chain® - E6Result: With e-chain® - E6, the supply of energy for wafer handling in chip production involving acceleration rates of up to 4m/s2 and speeds of up to 6m/s is not a problem.

Learn more

Industry: Medical technology

Result: drylin® TR high helix thread nuts were used in laboratory equipment for handling fluids. The advantage for the cleanroom is their low coefficient of friction, higher efficiency and no lubrication is necessary, which prevents contamination.

drylin® TR high helix thread nuts for laboratory equipment

Solution: drylin TR high helix thread nutsResult: drylin® TR high helix thread nuts were used in laboratory equipment for handling fluids. The advantage for the cleanroom is their low coefficient of friction, higher efficiency and no lubrication is necessary, which prevents contamination.