Change Language :

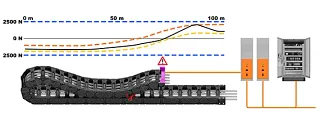

EC.PR position-dependent push/pull force measurement

Protect the entire length of travels of up to 1,000m

Avoid system-dependent imprecision for push/pull force monitoring systems on travels longer than 150 m. System-dependent imprecision due to static force limits for travels > 150m are a thing of the past. Now there is the new EC. PR module. Here, force limits are dynamically adjusted with information from PLC control systems, OPC-UA servers, or analogue (4-20 mA) path measurement systems (Profinet /EC. PP). This reduces repair cost and effort; replacing a stacker reclaimer, for example, costs $30,000 or more.

Tech up

- Position-dependent reduction of maximum push/pull force limits at which the system is shut down – freely

defined for each point along the travel. - Position information via additional modules from Siemens PLC, OPC-UA servers, or analogue or digital path measurement systems.

Cost down

- Avoid unplanned repair costs such as $49,798 or more for replacing a stacker reclaimer.

- Integration into existing control concepts and switch cabinets

- Standard strain gauge sensors and load cells can be used in igus® floating moving ends

Proof

- Tested on a 200-m field test stand in the world's largest laboratory for dynamic energy transmission systems

- Video 1 of the igus® test stand

- Video 2 of the igus® test stand

Sustainability

- For example, save 32kg of CO² emissions for each repair deployment avoided. 2

- Less raw material required thanks to the option of partial repair instead of complete replacement.

- More about the igus® contribution to Plastic2Oil

Potential application areas

We have developed iglidur EC.PR for this purpose

- Long travels > 150m in project business

- Stacker - reclaimer

- Automatic cranes

Sample can be delivered within 14 days for BETA TEST projects. Delivery time for BETA test projects: 14 days

You might also be interested in

1* igus® application at Tata Steel in Haldia, India with a travel of 480m and a chain length of 240m was able to avoid a replacement worth about $30,000

2* Randomly chosen Mercedes vehicle built in 2015 with 160 grammes of CO²/km at a randomly defined 100-km departure/arrival