Application examples with smart plastics

smart examples with energy chains + cables

smart examples for bearing technology

Complete smart plastics package on RMG crane

Which smart plastics technology is used?Condition monitoring:

EC.P for determining the push/pull forces, EC.B for determining chain breaks, CF.P for measuring the tensile force on cables, EC.M sensor for the movement data and EC.W sensor for measuring the abrasion on the energy chain.

Predictive maintenance:

i.Cee. local

Why is it used?

For maximum system protection, overview, maintenance management, product service life and safety.

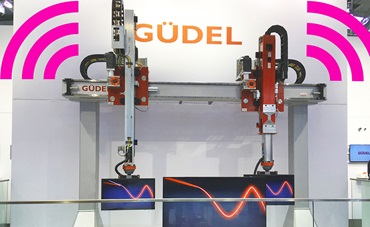

Maintenance planning for linear robot

Which smart plastics technology is used?EC.M sensor for motion data and EC.W sensor for the measurement of abrasion along the energy chain

Why is it used?

The two sensors transfer the measured values via the i.com module (now i.Cee module) directly to Güdel's condition monitoring system, which evaluates the data and makes maintenance predictable.

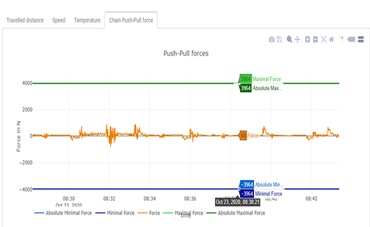

Which smart plastics technology is used?

EC.P pull force monitoring system for the energy chain

Why is it used?

The sedimentation tank surface scrapers in wastewater treatment plants operate very slowly, but do so 24/7 and it is possible that damage to the system will not be detected until hours later. In order to shut down the plant in an emergency, the EC.P module is used in many wastewater treatment plants with an energy chain, shutting down the plant in an emergency so that the damage can be rectified and total damage is avoided.

EC.P pull force monitoring system for the energy chain

Why is it used?

The sedimentation tank surface scrapers in wastewater treatment plants operate very slowly, but do so 24/7 and it is possible that damage to the system will not be detected until hours later. In order to shut down the plant in an emergency, the EC.P module is used in many wastewater treatment plants with an energy chain, shutting down the plant in an emergency so that the damage can be rectified and total damage is avoided.

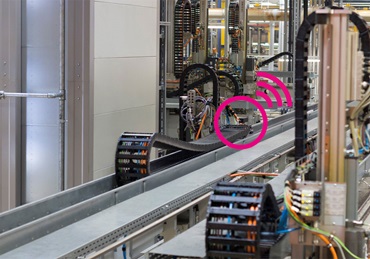

Condition monitoring for automotive parts suppliers

Which smart plastics technology is used?EC.B sensor for breakage monitoring + EC.W for measurement of the abrasion along the energy chain.

Why is it used?

For the customer, it is important that subsequent damage to the equipment be prevented in the event of chain breakage. The EC.B module detects a breakage in the energy chain and switches the equipment off or at least indicates a fault. By means of the EC.W sensor, the abrasion along the e-chains is measured, as a result of which maintenance is predictable

Cable monitoring for bread packaging machinery

Which smart plastics technology is used?

CF.Q = Cable monitoring

Why is it used?

At 80 cycles per minute, several million cycles are reached within just a few months. Of course, the machine should operate for many years without failing. CF.Q does not lengthen the service life of the cables but can calculate their exact service life and thus makes maintenance 100% predictable.

CF.Q = Cable monitoring

Why is it used?

At 80 cycles per minute, several million cycles are reached within just a few months. Of course, the machine should operate for many years without failing. CF.Q does not lengthen the service life of the cables but can calculate their exact service life and thus makes maintenance 100% predictable.

Predictive maintenance in train washing station

Which smart plastics technology is used?

EC.M motion sensor, EC.W abrasion sensor, EC.B breakage sensor, i.Cee:plus for the evaluation of sensor data, i.Cee:net for the transfer of data to the i.Cee dashboard

Why is it used?

The purpose of condition monitoring of the built-in components is to ensure that, if damage occurs, the machine is shut down, whereby the predictive maintenance system provides an optimum maintenance plan for the built-in components.

EC.M motion sensor, EC.W abrasion sensor, EC.B breakage sensor, i.Cee:plus for the evaluation of sensor data, i.Cee:net for the transfer of data to the i.Cee dashboard

Why is it used?

The purpose of condition monitoring of the built-in components is to ensure that, if damage occurs, the machine is shut down, whereby the predictive maintenance system provides an optimum maintenance plan for the built-in components.

Maximum safety on a rail-mounted gantry crane (RMG)

Which smart plastics technology is used?i.Cee with EC.B breakage detection + EC.M motion sensor

Why is it used?

Depending on the damage, the number of unscheduled shutdowns of a crane quickly reaches the four or five digit range. To ensure that energy chain wear is detected in good time, the i.Cee System determines the optimum time for maintenance.

At the same time, the system increases machine safety and also protects people, as no damage occurs.

Increase safety for your crane

Plain bearing bushings in agricultural machinery

Intelligent bearings in agricultural machinery

Which smart plastics technology is used?i.Sense bushing

Why is it used?

Due to heavy loads and the additional effects of dirt, vibration and weather, a huge amount of stress is placed on bearing points, but they are sometimes maintained irregularly as well or, due to the difficulty of access, are sometimes badly or only partly maintained. This is where the smart bearing is of help as it always reports the current condition of components and how worn they are.

Submit an enquiry for smart bearings

Smart e-chain® and cables

Use smart plastics to stay abreast of how your chain is doing.

Our intelligent e-chain® systems are already reliably in use in hundreds of thousands of applications worldwide - from beverage machines and CNC machines to steel mills.Learn More

Smart bearing technology

Don't let a defective plain bearing ruin your day.

Smart plain bearings are great for sensitive or hard-to-reach spots on a machine, since they allow the bearing's condition to be assessed at any time.Learn More

Smart Applications

Customer application examples with smart plastics

Whether a new project for Industry 4.0 or efficiency-driven retrofitting - our smart plastics solutions are available as universal modular systems and can be individually adapted to any system.Learn More