Change Language :

3D printed lead screw threads and nuts

Configure and order 3D printed threads online

Self-lubricating lead screw technology from the largest online thread shop in the world

Trapezoidal, high helix, and metric threads of high performance plastics with more than 5,000 variants available directly from stock. Discover drylin® catalog parts, special solutions and configurators for threads, lead screw nuts, and lead screw drives as complete solutions.

dryspin® thread technology: High efficiency and low wear

The patented dryspin® high helix thread technology was developed by igus® and offers numerous advantages over conventional high helix threads:

- The flat thread angle converts the exerted power efficiently to a translational movement.

- The harmonized geometries of plastic nut and lead screw give high helix threads an especially long service life and high efficiency.

- The rounded tooth geometry allows the thread systems to operate quietly and without vibration under load.

- The larger spaces between the individual threads increase the share of slide-optimized plastic in the threads by a factor of 1.3. This effect and greater efficiency allow a service life that is up to five times as long as that of conventional high helix threads.

3D printed thread wear test

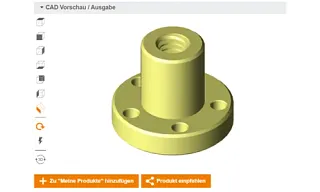

Free-of-charge CAD configurator for lead screw nuts

How to design the perfect lead screw nuts for your application:

- Select the desired trapezoidal lead screw nut shape.

- Select the thread direction and type.

- Indicate the width and outer diameter.

The 360° view is updated to reflect your entries. - Download the file in the desired format, add it to your CAD software, and edit it further or upload it directly in STEP format to our 3D printing service and order the part.

Thread manufacture

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert