Change Language :

autoglide 5 - energy and data transmission installed in one hour

Cost-effective e-chain for intralogistics and crane systems with 88% lower assembly time

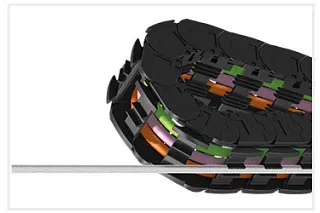

The igus® system autoglide 5 transmits energy, data, fluids and air in one system safely and almost maintenance-free at a cost-effective price, including e-chain® 2400.07AG.075.0, steel cable guide, bus cable assembly and 5 individual wires of 6 mm² each. The metal rope included in delivery is stretched across the floor. Alternatively, guidance via a plastic rope or a profile is also possible.

The e-chain can travel safely on the rope. The underside of the chain links has a guide element in the middle, so that the energy chain can rest safely on the rope. autoglide elements ensure wear-resistant and precise rolling of the upper run of the chain.

Technical data:

| Travel | Speed | Noise during operation |

|---|---|---|

| 80m | 4 m/s | 63dB (A) at 2 m/s |

Tech up

- Energy, data, air and liquids in ONE system

- Often saves two or more other systems for transmitting data

- 4m/s speed

- 80m travel

- Quiet operation: 63db(A) at 2m/s

- 50% hall floor remains free, no guide trough needed

Cost down

- Assembly times 88% shorter than those for a conventional standard solution with guide troughs

- Ready for installation with e-chain 2400.07AG.0750, steel cable troughs, prefabricated bus cable, and 5 6mm2 wires.

- Available as a harnessed system with cables, hoses and connectors

- Less maintenance and cleaning requirements

Proof

- Tested in the igus laboratory and by Company Beewen GmbH

- Suitable for other industries and applications: storage and retrieval units, indoor cranes, port operators, sports facilities, theatres, machine tools, linear robots

Sustainability

- Energy consumption for autoglide 5 manufacture is 64% lower than that of an energy chain with aluminum trough on a 50m travel

- To recycle integrated energy chain through the igus chainge program free of charge

Complete solution

Travel: 10 - 60m]

1 complete set consists of:

- 2400.07AG5 energy chain

- AG5 and AG individual parts

- Separators every 2nd link, pre-assembled

- Track holder for AG

- Upper run guide

- Mounting brackets for moving end

- Steel wire cable

- Cable tensioning unit

- Fixed end module

- Installation/mounting instructions

4-part energy chain

| Part No. | Inner height | Inner width | Bend radius*** |

|---|---|---|---|

| E4.32.10AG5* | 32mm | 100mm | 100/125/150/175/200mm |

| E4.32.112AG5* | 32mm | 112mm | 100/125/150/175/200mm |

| E4.32.12AG5* | 32mm | 125mm | 100/125/150/175/200mm |

| E4.32.15AG5* | 32mm | 150mm | 100/125/150/175/200mm |

| E4.32.17AG5* | 32mm | 167mm | 100/125/150/175/200mm |

| E4.32.20AG5* | 32mm | 200mm | 100/125/150/175/200mm |

| E4.32.262AG5* | 42mm | 262mm | 125 / 150 / 160 / 175 / 200mm |

| E4.42.10AG5* | 42mm | 100mm | 125 / 150 / 160 / 175 / 200mm |

| E4.42.112AG5* | 42mm | 112mm | 125 / 150 / 160 / 175 / 200mm |

| E4.42.12AG5* | 42mm | 125mm | 125 / 150 / 160 / 175 / 200mm |

| E4.42.15AG5* | 42mm | 150mm | 125 / 150 / 160 / 175 / 200mm |

| E4.42.17AG5* | 42mm | 167mm | 125 / 150 / 160 / 175 / 200mm |

| E4.42.20AG5* | 42mm | 200mm | 125 / 150 / 160 / 175 / 200mm |

| E4.42.262AG5* | 42mm | 262mm | 125 / 150 / 160 / 175 / 200mm |

autoglide 5 Advantages

Until now, many industries, including storage and retrieval systems, have been relying on busbar systems for power and data transmission in tight, compact spaces and for fast lane movements. These are very simple in construction and very cost-effective. Their major disadvantage is that they are expensive to maintain and must be cleaned regularly to avoid contact faults. Furthermore, they can usually only transmit energy.

autoglide5 provides a new solution with the following benefits:

- Can easily be installed in the aisle on a rope or a profile

- Cost-effective price

- 88% shorter assembly time compared to aluminum troughs

- Long-lasting, maintenance-free and easy to clean

- Energy, data, air and liquids in ONE system

- 4m/s speed

- 80m travel

- Quiet operation: 63db(A) at 2m/s

- Hall floor remains free, no guide trough needed

- Available as harnessed system with cables, hoses and connectors

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert