Change Language :

Subtractive Manufacturing and Custom Bar Stock Machining Services

igus® uses plastic bar stock consisting of iglide® high-performance polymers to manufacture individual components and prototypes according to your custom requirements with subtractive manufacturing. Our subtractive manufacturing services are ideal for prototyping and small-scale orders such as an individual product series, and the wide selection of sizes available means nearly any application can make use of our bar stock. Our iglide® materials have a range of properties, such as low coefficients of friction, high temperature resistance, and with certain materials FDA compliance. All materials are resistant to dust, dirt, corrosion and humidity, making our custom bar stock an ideal solution for any possible application.

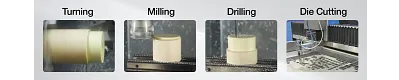

Browse our Custom Machining Methods

Browse our Custom Machining Materials

Browse the Engineer's Toolbox

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert