Change Language :

Function check at the touch of a button - linear carriage with wear measurement

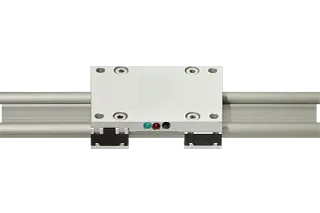

drylin® W i.Sense linear carriage with LED display with new installation sizes

With the new drylin® i.Sense linear carriage, the function and wear test is carried out simply at the push of a button. No integration in IT environments, no interface issues. When the green flashes everything is all right and the linear carriage can be operated further. The red LED recommends a bearing replacement and this can be easily done. In less than 30 seconds directly on the rail without disassembly. In addition to installation sizes 10 and 16, the i.Sense carriage is now also available in installation size 20 and is suitable for our drylin® toothed belt axes in the modular system range and also as a basis in robotics as the 7th axis.

Tech up

- Function check at the touch of a button directly on the linear carriage

- Wear sensor directly integrated in the liner

- Predictable maintenance signal when the wear limit of 0.5mm is reached

- Suitable for drylin® W linear systems, drylin® ZLW toothed belt axes and 7th axis

Cost down

- Direct use without integration into IT system

- Liners for bearing replacement can be ordered as a set

- Quick bearing replacement of drylin® W exchange bearings within seconds

- Reduced downtime since bearings can be changed without dismantling the linear unit

Proof

- Service life and function tested in the igus® laboratory; can be calculated online (on ZLW-1040 toothed belt axis, 100N load at a stroke length of 3,000mm, speed of 0.5mm/s and acceleration of 1m/s²)

- Long-life batteries (three years)

Sustainability

- Long service life thanks to linear liners made of iglidur® J200

- All metallic components can be reused when replacing bearings

- 100% lubrication-free operation