Change Language :

2021 smart plastics® news

Moving energy made smart – through innovation and sustainability

Our task is to constantly develop new innovations in e-chains and cables. This enables us to help you to save costs and further increase the quality of machines and systems at the same time, in other words "Tech up. Cost down".

We at igus also accept the responsibility to contribute to the reduction of plastic waste and improvement of recycling: when energy chains reach their end of service life, we have them processed in the igus undefined . Also learn undefinedabout our investment in chemical recycling by Mura Technology Limited.

Now 4 condition sensors in one box ...

... with the new i.Sense:modul II

The generally overhauled i.Sense:modul Generation 2 offers you a multitude of new possibilities and application scenarios for smart condition monitoring. Specifically, with this new generation, four status sensors can be connected to just one switch cabinet module at the same time, which means considerable space and cost savings. And not only in the switch cabinet, but also in the chain itself, as only one cable needs to be run for every four sensors.

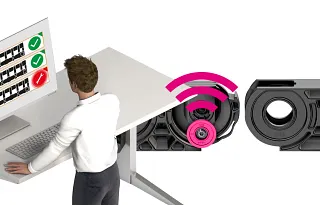

A whole lot of Industry 4.0 in one device ...

... with the new 2nd generation i.Cee:plus module

i.Cee = "I see ahead" - now also in our customers' network environments and IoT concepts. The 2nd generation of the i.Cee:plus module creates the optimal framework conditions for predictive maintenance entirely in the interest of the customer. This is because the possibility of seamless integration into the designated network environments of the respective applications enables the creation of the most diverse Industry 4.0 use cases.

Condition monitoring on bus cables ...

... thanks to a new measuring method without any sacrificial cores at all

Always with the goal of saving unnecessary costs and resources, we have further optimised i.Sense CF.D, the condition monitoring of Ethernet cables in e-chain systems and triflex R applications. The new measuring method determines the data transmission properties of the cables during operation using high-frequency technology. This eliminates the need for additional sacrificial cores, which is good for the budget and the environment.

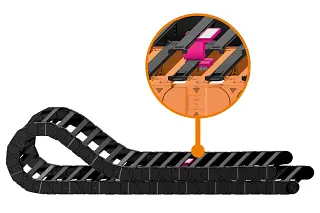

Predictive maintenance for heavy-duty applications ...

... with smart plastics in the new P4.1 rol e-chain®

In the latest development stage of the igus rol e-chains, the use of maintenance-free, tribo-polymer plain bearings in the connection of the e-chain links also considerably lengthens the service life. As an option, the new P4.1 can be fitted with smart monitoring sensors. Thereby from a defined wear limit, a signal is issued to the igus icom communication module and with it maintenance can be planned in advance. The sensor is thereby integrated into a standard side part of the chain, which does not lead to any restrictions in the usable inner width.

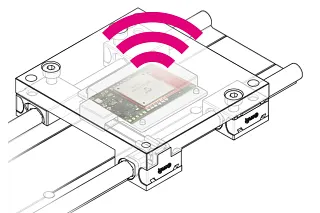

Finally also for drylin W profile guides ...

... Connection to the Internet of Things (IoT) with i.Cee

A measurement and data transmission unit is built into the carrier plate of the drylin carriage to implement a wide range of Industry 4.0 use cases. This communicates via the industry-standard LoRa radio standard up to a range of 50m with the intelligent i.Cee:plus module. This can then be used for all kinds of integration into customer networks or other IoT concepts. Of course, this can also be implemented locally using a standard CAT5 patch cable.

Lifelong condition monitoring with ...

... EC.W LoRa separator with solar power supply

This separator powered with solar electricity is always bursting with energy. Changing the battery of the installed module is no longer necessary.

Abrasion at the crossbar of the chain can be measured without problems and in a resource-friendly way.

3D printed wear-resistant parts with sensors for ...

... the fast production of intelligent special parts

Components made with the multi-material printing process enable predictive maintenance for quickly manufactured special parts, so that machine downtime and maintenance work can be reduced sustainably. Due to the sensor layer, the intelligent 3D isense components issue a warning before the wear limit is reached or if overloading occurs.

Finally, multiple asset connection possible ...

... with the i.Cee.box incl. LoRa receiver & antenna

The i.Cee. box manages to escape the control cabinet of the machine and offers the possibility to transmit data via LoRa radio transmission standard. Therefore, the box is an alternative to the i.Cee. plus module, which is installed in the control cabinet.

smart plastics selection guide:

choose the solution that suits you best