Change Language :

iglide® A290 - Material data

Materials table

General features

Unit

iglide® A290

Test method

Density

g/cm³

1,41

Color

White

Max. moisture absorption at 73° F / 50% R. H.

% weight

1,7

DIN 53495

Max. moisture absorption

% weight

7,3

Coefficient of surface friction, dynamic, against steel

µ

0,13 - 0,40

p x v value, max. (dry)

psi x fpm

6,600

Mechanical properties

Modulus of elasticity

psi

1,276,000

DIN 53457

Tensile strength at 68° F

psi

36,260

DIN 53452

Compressive strength

psi

13,200

Permissible static surface pressure (68° F)

psi

10,150

Shore D hardness

88

DIN 53505

Physical and thermal properties

Upper long-term application temperature

°F

284

Upper short-term application temperature

°F

356

Lower application temperature

°F

-40

Thermal conductivity

[W/m x K]

0,24

ASTM C 177

Coefficient of thermal expansion (at 73°F)

[K-1 x 10-5 ]

7

DIN 53752

Electrical properties

Specific volume resistance

Ωcm

> 1011

DIN IEC 93

Surface resistance

Ω

> 1011

DIN 53482

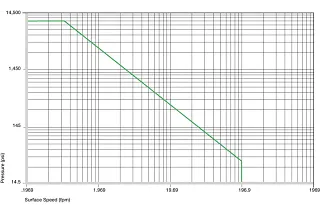

Permitted p x v values

For iglide® A290 plastic bushings running dry against a steel shaft, at 68° F.

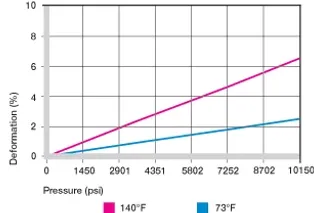

Figure 9.2: Deformation under load and temperatures

Surface pressure

iglide® A290 plastic bushings are an advanced development for the use in food and pharmaceutical industry. Compared to the bushings made of iglide® A200, the tribological properties could be significantly improved.

iglide® A290 plastic bushings have a recommended maximum surface pressure of 10,150 psi. At this load, the deformation at room temperature is only 2.5%. A plastic deformation is close to zero up to this load. However, it is also affected by the cycle time.

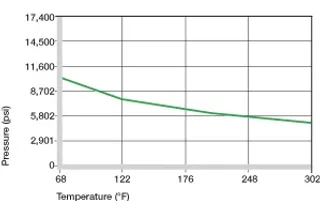

Figure 9.3: Maximum recommended surface pressure dependent on the temperature

Temperatures

The short-term permitted maximum temperature is 356° F.

With increasing temperatures, the compressive strength of iglide® A290 plastic bushings decreases. The diagram 9.3 clarifies this connection.

The temperatures prevailing in the bushing system also have an influence on the bushing wear. The wear increases with rising temperatures, and the influence is especially marked from 248° F temperature onwards.

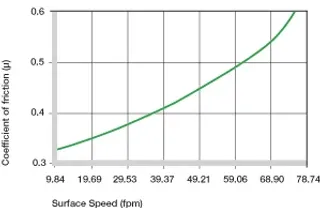

Figure 2.4: Coefficients of friction dependent on the surface speed, p = 108 psi

Friction and wear

The coefficient of friction alters like the wear resistance with increasing load and surface speed.. With increasing speed and constant load, the coefficient of friction steadily rises. In contrast a reverse behavior is noticed at increasing load and constant speed (see Figures. 9.4 and 9.5) Friction and wear depend to a high degree on the reverse partner. Very smooth shafts increase the coefficient of both friction and wear. iglide® A290 proves to be relatively insensitive to shaft surfaces and retains a 0.4 friction coefficient µ with average surface finishes of Ra = 0.4 to 1.6 µm.

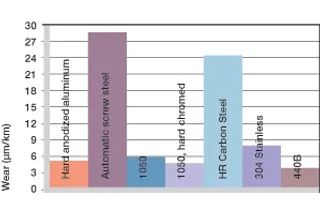

Fig. 2.7: Wear, rotating application with different shaft materials, load p = 108 psi, v = 98 fpm

Shaft materials

The graph displays a summary of the results of tests with different shaft materials conducted with plastic bushings made of iglide® A290.

Compared to iglide® A200, the improved tribological properties of iglide® A290 are also reflected in the coefficients of wear. At low loads, the differences in the wear resistance of the combinations of iglide® A290 with different shaft materials are very distinct. Figure 9.8 shows that the advantage of hard-chromed shafts increases with rising load. This counter partner is also well-suited for pivoting applications and are frequently found in packaging machines. Other hardened surfaces are also recommended for oscillating movements, for example 1050 hardened and ground steel.

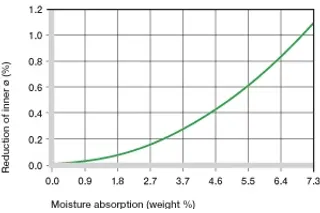

Figure 9.10: Influence of moisture absorption of iglide® A290 plastic bushings

Radioactive rays

iglide® A290 plastic bushings are radiation resistant up to a radioactive intensity of 3 x 10² Gy.