Change Language :

iglide® H - Material data

Materials table

General features

Unit

iglide® H

Test method

Density

g/cm³

1.71

Color

Gray

Max. moisture absorption at 73° F/50% R. H.

Wt.-%

< 0.1

DIN 53495

Max. moisture absorption

Wt.-%

0.3

Coefficient of surface friction, dynamic, against steel

µ

0.07 - 0.2

p x v value, max. (dry)

psi x fpm

39,000

Mechanical properties

Modulus of elasticity

psi

1,813,000

DIN 53457

Tensile strength at 68° F

psi

25,380

DIN 53452

Compressive strength

psi

11,750

Permissible static surface pressure (68° F)

psi

13,050

Shore D hardness

87

DIN 53505

Physical and thermal properties

Upper long-term application temperature

°F

392

Upper short-term application temperature

°F

464

Lower application temperature

°F

-40

Thermal conductivity

[W/m x K]

0.6

ASTM C 177

Coefficient of thermal expansion (at 73° F)

[K-1 x 10-5 ]

4

DIN 53752

Electrical properties

Specific forward resistance

Ωcm

< 10 5

DIN IEC 93

Surface resistance

Ω

< 10 2

DIN 53482

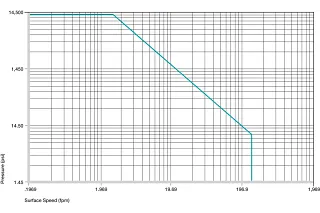

Permitted p x v values

For iglide® H plastic bushings with 0.039 inch wall thickness in dry operation against a steel shaft, at 68° F, installed in a steel housing.

iglide® H is a fiber-reinforced thermoplastic material especially developed for applications in high atmospheric humidity or under water. Plastic bushings made of iglide® H can be used completely free of lubrication; in application in the wet area, the surrounding media acts as additional lubricant.

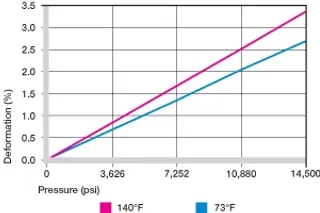

Figure 12.2: Deformation under load and temperatures

Surface pressure

Figure 12.2 shows the elastic deformation of iglide® H with radial loads. Under the maximum recommended surface pressure of 13,050 psi, the deformation amounts to about 2.5%.

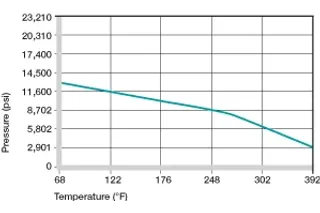

Figure 12.3: Maximum recommended surface pressure dependent on the temperature

Temperatures

iglide® H is an extremely temperature-resistant material. With a short-term permitted maximum temperature of 464° F, the iglide® H plastic bushings can be subjected, for example, to a paint drying process at low loads.

With increasing temperatures, the compressive strength of iglide® H plastic bushings decreases. Fig. 12.3 clarifies this connection. The temperatures prevailing in the bushing system also have an influence on the bushing wear. The wear rises with increasing temperatures. With increasing temperature in the range between room temperature and 302° F, compressive strength and wear, if only to a minor degree, drop for the iglide® H.

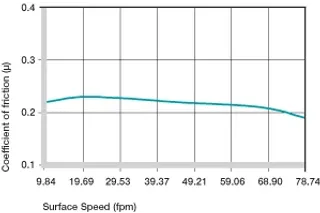

Figure 2.4: Coefficients of friction dependent on the surface speed, p = 108 psi

Friction and wear

Similar to wear resistance, the coefficient µ of friction also changes with the load. Notice that the coefficient of friction µ is slightly reduced with the increase in the surface speed, when the pressure stays the same.

Since the shaft material also has a large effect on the friction and wear, correct shaft selection is important for iglide® H. Shafts that are smoother than 4 rms increase the coefficient of friction. For applications with high loads, we recommend hardened and ground surfaces with an average roughness range of 12-16 rms.

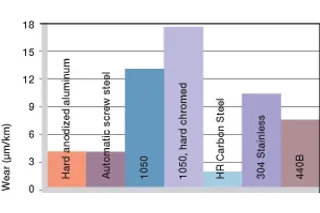

Fig. 2.7: Wear, rotating application with different shaft materials, load p = 108 psi, v = 98 fpm

Shaft materials

The graph displays a summary of the results of tests with different shaft materials conducted with plastic bushings made of iglide® H. The results clearly show that in rotating and oscillating applications the correct shaft selection is critical. For rotating applications, shafts made of 1050 hardened, ground steel and HR Carbon steel show the best wear values, the 3030 stainless steel shaft is best suited for oscillating movements. Also, hard chromed shafts with iglide® H plastic bushings are only recommended for low loads.

Please contact us in case the shaft material scheduled by you is not included in this diagram.