Change Language :

iglide® V400 - Material data

Materials table

General features

Unit

iglide® V400

Test method

Density

g/cm³

1,51

Color

White

Max. humidity absorption at 23° C/50% R. H.

Wt.-%

0,1

DIN 53495

Max. water absorption

Wt.-%

0,2

Mechanical properties

Bending E-module

MPa

4.500

DIN 53457

Bending strength at 20° C

MPa

95

DIN 53452

Maximum recommended surface pressure (20° C)

MPa

45

Shore D hardness

74

DIN 53505

Physical and thermal properties

Upper long-term application temperature

°C

200

Upper short-term application temperature

°C

240

Upper short-term ambient temperature1)

°C

250

Lower application temperature

°C

-50

Electrical properties

Specific forward resistance

Ωcm

> 1012

DIN IEC 93

Surface resistance

Ω

> 1012

DIN 53482

- Without additional load; no gliding movement; relaxation not excluded.

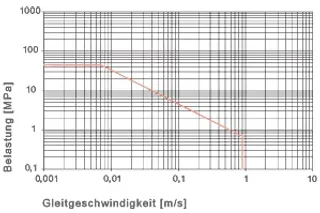

Permitted p x v values

For iglide® V400 bearings with 1 mm wall thickness in dry operation against a steel shaft, at 20° C, installed in a steel housing.

Bearings made of iglide® V400 are an excellent solution when it comes to simultaneous high elasticity, toughness and wear resistance at high temperatures. They exhibit an excellent chemical resistance and are suitable for applications in which the bearings confront special demands. iglide® V400 bearings are extremely suitable for pairing with softer shaft materials like V2A.

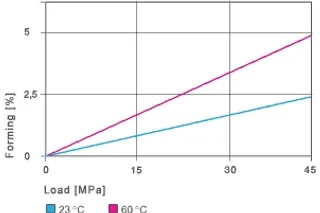

Figure 20.2: Deformation under load and temperatures

Surface pressure

iglide® V400 bearings are not suitable for high pressures or static high loads. However they are characterized by a high wear resistance all the way up to the maximum recommended surface pressure. Moreover the limit of the permitted loads at 100° C is still higher with 20 MPa. The high elasticity is seen also in the curve that states the deformation under the permitted loads.

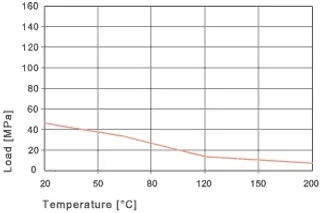

Figure 20.3: Maximum recommended surface pressure dependent on the temperature

Temperatures

The long-term permitted maximum application temperature is 200° C, however the bearings should be mechanically secured at these temperatures. But the wear resistance of the bearing is excellent indeed and claims a top position among all iglide® materials. With increasing temperatures, the compressive strength of iglide® V400 bearings decreases. Fig. 20.3 clarifies this connection.

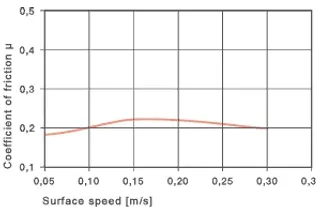

Figure 2.4: Coefficients of friction dependent on the surface speed, p = 0.75 MPa

Friction and wear

The coefficient of friction is dependent on the bearing's stressing capacity. When p x v values exceed the permitted range, the bearings respond with a rise in coefficient of friction. As long as the loads are in the permitted range, the coefficient of friction of the bearing is very low. Furthermore, the coefficients of friction of iglide® V400 are very constant. No other iglide® bearing material exhibits a lower variance in the coefficients of friction, even when the shaft material is altered.

In wear, the iglide® V400 bearings show better values in rotating applications than in pivoting motions.

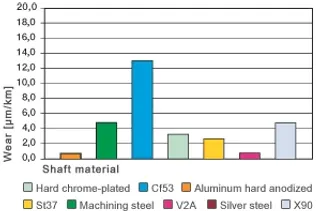

Fig. 2.7: Wear, rotating application with different shaft materials, load p = 0.75 MPa, v = 0.5 m/s

Shaft materials

As mentioned in the section on friction and wear, the iglide® V400 bearings show only a very low dependency on the shaft materials with regard to the friction of bearing systems. This applies even when plastic and ceramic shafts besides steel ones are tested. Greater is the influence on wear resistance. Here already at low loads (0.75 MPa) there could be significant variations, as Figure 20.7 shows.

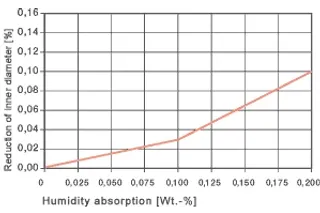

Figure 20.10: Influence of humidity absorption of iglide® V400 bearings

Radioactive rays

iglide® V400 bearings are resistant up to a radioactive intensity of 2 x 104 Gy. Higher radiations affect the material and can lead to the loss of important mechanical properties.