igus-icon-lupe

igus-icon-lupe

igus-icon-lupe

igus-icon-lupe

igus-icon-lupe

igus-icon-lupe

igus-icon-lupe

igus-icon-lupe

igus-icon-lupe

igus-icon-lupe

1 of 10

igus-icon-arrow-left

igus-icon-arrow-right

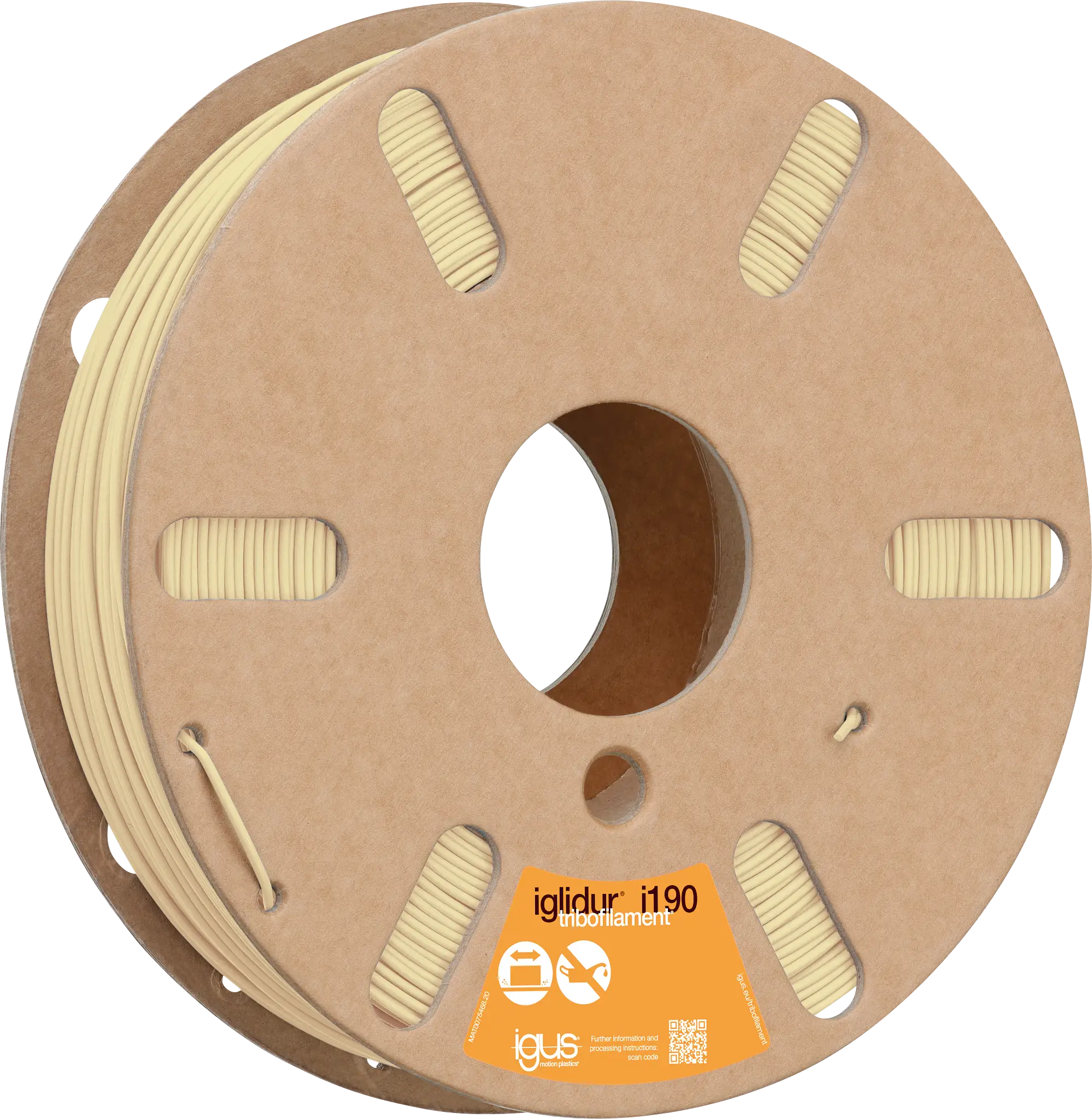

- Flexural strength 80 MPa, best iglide filament

- Can be processed easily on commercially available 3D printers

- Excellent service life - 50 times higher abrasion resistance than ABS

- Self-lubricating and maintenance-free

- Application temperature: 90°C (after component tempering)

igus-icon-lieferzeit-dotI190-PF-0175-0750

1.75

750