igus-icon-lupe

igus-icon-lupe

1 of 2

- Belt deflection 100% dry-running

- Fulfils the fire prevention requirements of the Federal Aviation Administration of the USA (FAA) for aircraft interiors

- Low drive power

- The endurance runner at higher temperatures in the food sector

- Tight deflection radii

- Compliant with EC regulation 10/2011 EC

- Long service life of the belt

- FDA compliant

- Long service life

- For use with temperatures up to +356 °F (+180 °C)

igus-icon-lieferzeit-dotA350RLM-0309-50

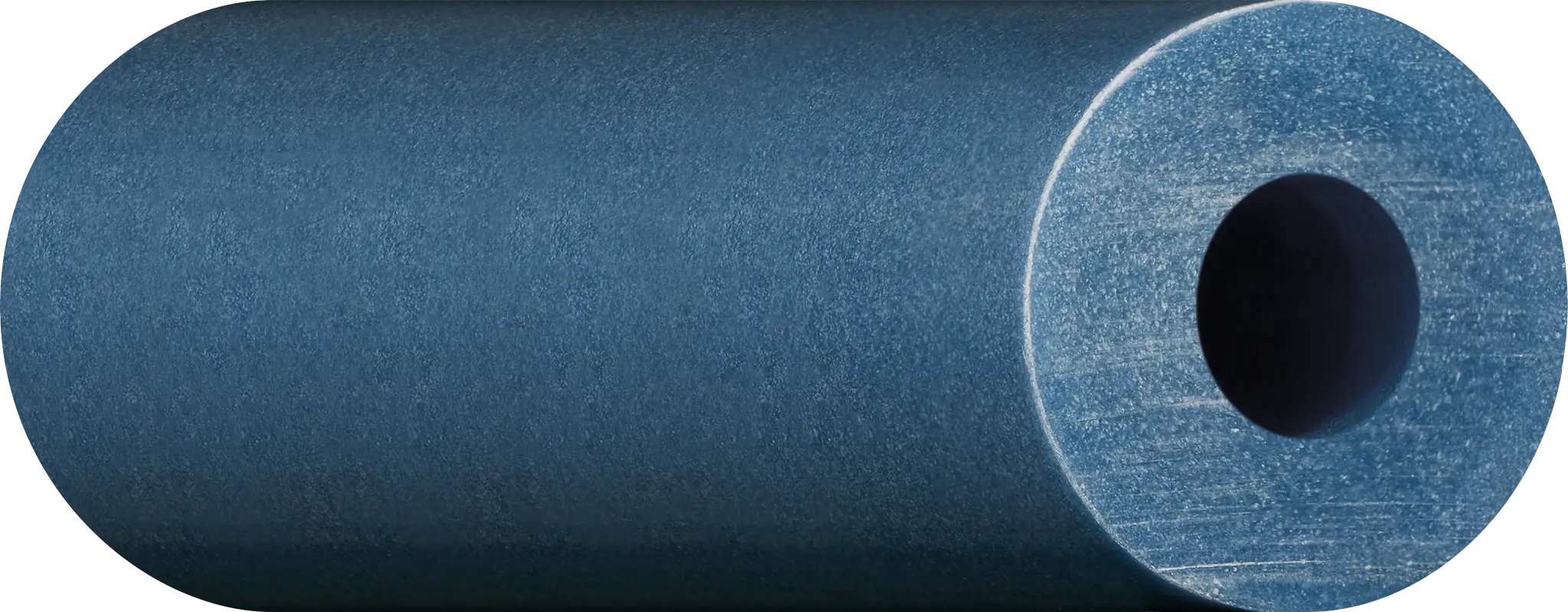

0.35 (9 mm)

0.12 (3.1 mm)