- Simple processing

- Suitable for all 3D printers

- High abrasion resistance at low sliding speeds

- Good mechanical properties

- Food compliant according to FDA and EU Regulation 10/2011

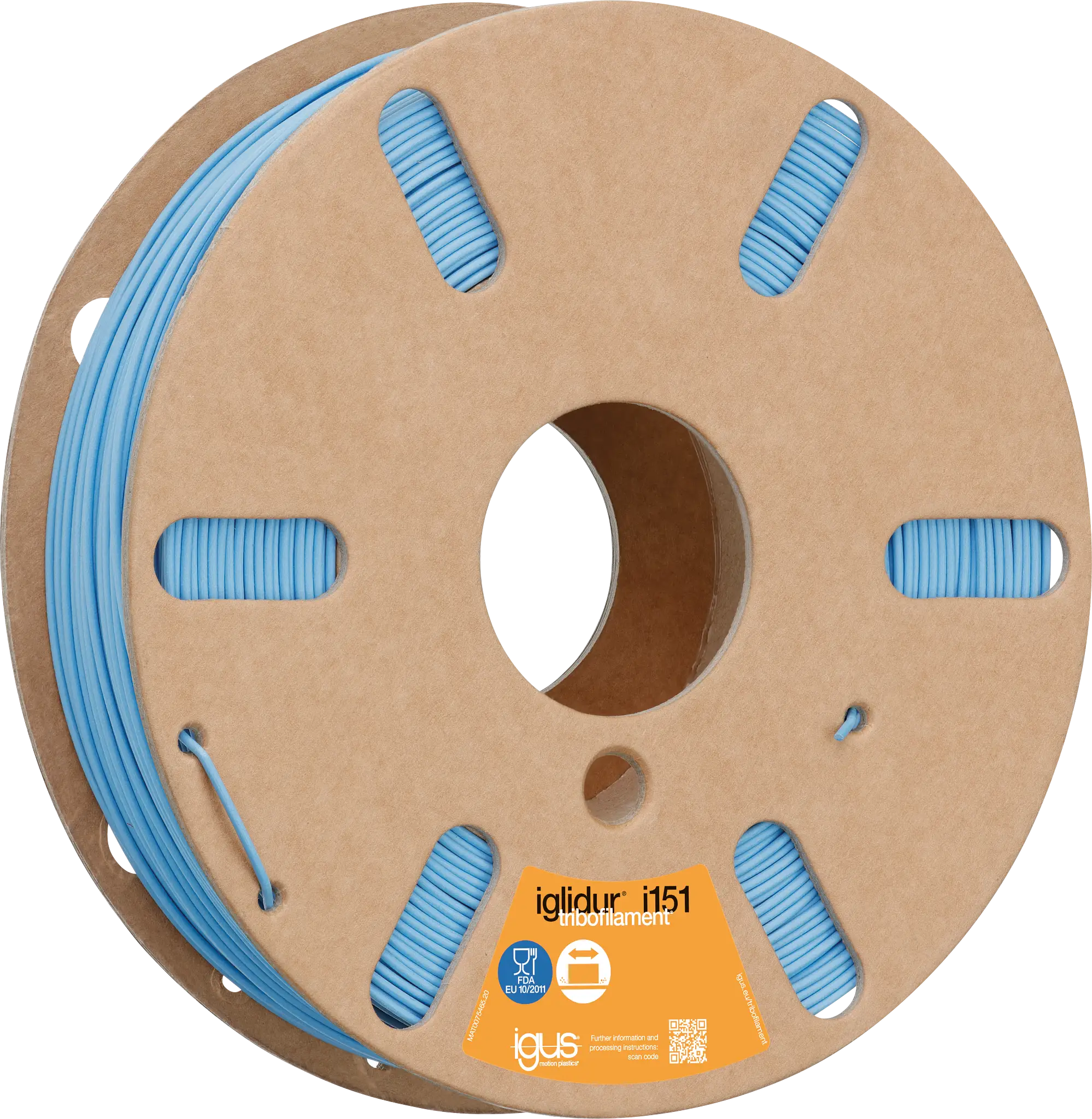

- Blue color for optical detectability

- Available also from our 3D printing service in 3 days

Change Language :