Change Language :

improve what moves with motion plastics

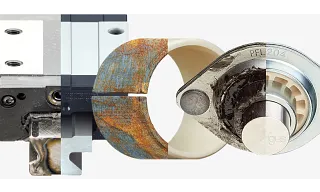

Bearing technology - self-lubricating and durable

Our materials and technology designs are diverse: high temperature, foodgrade, high load, UV and chemical resistant, plain bearings, linear technology, self-aligning bearings, gears, lead screws, 3D printing, automation and more. The core of our developments is friction optimisation. All material mixtures are improved with filler and solid lubricants so that low friction values are achieved and no external lubrication is necessary. There are no lubrication intervals for trouble-free operation. Our technology runs without maintenance interruption for as long as conditions permit. And since our materials are tailored to many conditions, this can be a very long time compared to other materials.

Pre-filled cable carriers with cables or pre-assembled with connector options

The best bearing technology cannot show what added value it brings if the machine does not run at all - because it does not get any energy. Data cables, power cables and cables with media are neuralgic points of a machine, the cause of a failure can often be found here. Our cable carriers and the cables optimized for movement have been developed to prevent failures and enable long service life. They are available as complete ready-to-install systems or as single parts.

Most recent awards for our products

More information about our plastics

Used in Various Industries

In 72 countries and more than 50 industries, motion plastics make our customers everyday life easier and improve their applications.

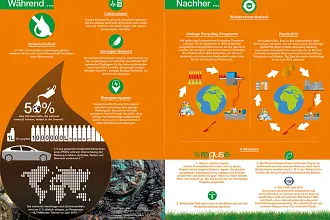

Sustainability

During production, in use and at the end of their service life: How sustainable are our high-performance plastics?

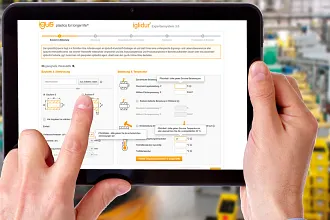

Online Tools

Easily configure your desired product online with our configurators, calculate service life, reduce process costs.

Over 15,000 tests per year

Our products pass through our 3,800 m2 test laboratory - the largest in the industry. We also test your individual application.

Certificates/Approvals

igus is audited and certified every year. This is how we ensure that each of our products meets our high quality standards.

Shipping and Delivery Times

Ready to ship in 24hrs. No minimum order quantity. Over 200,000 products ex-stock.

manus award

Every second year we award the most innovative plastic plain bearing applications of our customers. Here are the current winners:

vector award

Furthermore, every two years, we award prizes to exceptionally bold energy supply solutions from our customers. You can see the current award winners here: