Change Language :

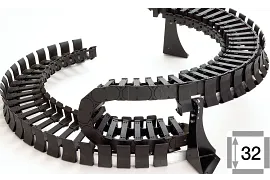

The new generation of twisterchain®: rugged & quiet for high loads

Higher loads and smoother running

With the new generation of new twisterchain circular chains, significantly improved smoothness coupled with higher stability could be achieved. The new twisterchain is modular in width, height and radius and can therefore be used very flexibly in applications where rotary motions up to 540° and more as well as rugged solutions are required.

- Sturdier, more additional load possible

- 25% less weight than the previous twisterchain

- Rotary speeds up to 1 m/s and more

- Rotary/Spiral movements up to 540°

- Highly dynamic and quiet operation (with a new trough)

- More cable-friendly, smoother interior

- Snap-open crossbars in the inner radius

- Over 1 million cycles tested successfully in the igus® laboratory (03/2010)

Typical industrial sectors and applications

- Robots, handling machines

- Packaging machines

- Glass machines

- General mechanical engineering etc.

Shop twisterchain: Snap-open along the inner and outer radius

Series TC32

- Inner height hi: 1.26" (32 mm)

- Inner width Bi: 3.44" - 5.91" (87.5 - 150 mm)

- Bend radii R: 3.94" - 9.84" (100 - 250 mm)

- Pitch: 2.2" (56 mm)

Series TC42

- Inner height hi: 1.65" (42 mm)

- Inner width Bi: 3.44" - 7.87" (87.5 - 200 mm)

- Bend radii R: 3.94" - 9.84" (100 - 250 mm)

- Pitch: 2.64 (67 mm)

Series TC56

- Inner height hi: 2.2" (56 mm)

- Inner width Bi: 4.92" - 7.87" (125 - 200 mm)

- Bend radii R: 5.91" - 15.75" (150 - 400 mm)

- Pitch: 3.58" (91 mm)

Selection criteria

Notes on the design of the twisterchain new.

twisterchain new selectiontwisterchain new 3D-CAD

Generation of complete twisterchain 3D models

twisterchain 3D-CAD modelstwisterchain new guide troughs

Learn more about new twisterchain guide troughs

twisterchain guide troughsFree samples and downloads

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert